Daily Preventive Maintenance Can Extend the Life of an Air Compressor

Think of a portable air compressor as a faithful dog: it’s loyal, obedient and supports its owner’s needs. And just like Fido needs regular walks, your compressor needs daily attention.

Whether you don’t feel qualified to perform maintenance tasks, or just don’t think there are enough hours in a day to devote to preventive care, rest assured that it’s actually a relatively simple and speedy process. A couple minutes before each use is all it takes to perform a few easy checks, and your compressor will work in top condition for years to come.

Before Each Use

Just like a dog needs a bath once in awhile, it is always a good idea to keep an air compressor clean. It’s easier to spot leaks and broken or loose components on a clean machine.

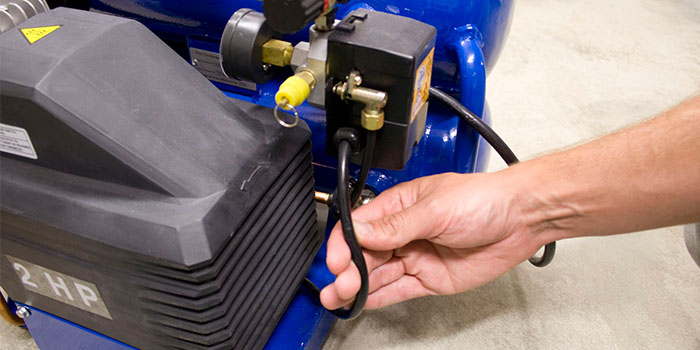

First, do a visual inspection. Check the hoses for kinks, the electrical wiring for cuts and fraying, and the tubing and piping for damage. Make certain all connections in those areas are tight and be sure to tighten any loose nuts and bolts. Also, check the controls, gauges, accessories and instruments for loose mountings or damage.

Next, check the pump oil level. Place the compressor on a flat surface, then remove the oil fill plug and check the level. Insert a screwdriver into the crankcase and inspect the oil for signs of contaminants, such as water or dirt; if found, change the oil, otherwise just change it annually. If a gas engine powers the compressor, check its oil level, too. It also should be changed every year.

Depending on what the air compressor will be used for, the air filter may need to be changed. As long as the correct filter is being used, it only needs to be replaced every few months. There are two types of filters: standard and coalescing. The former will trap dust particles, while the latter will remove water and oil from the air. For some applications, such as spraying paint, an air dryer should be used with the coalescing filter so that moisture is removed from the lines. On the other hand, some tools function better with moisture. When using a nail gun, for instance, an operator may want to add oil to the line with a lubricator.

During and After

If a dog growls, one would assume there is a problem. The same goes for air compressors. Knocking or vibrating could indicate a worn connecting rod or piston pin, dirt on the piston, or a loose flywheel or pulley. Chatter at the pressure switch or magnetic starter may indicate the switch needs to be adjusted or replaced.

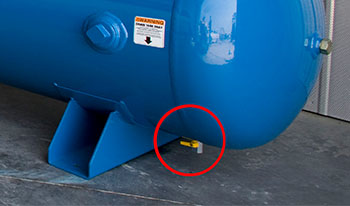

The final task is to drain water from the tank. Depending on the humidity level, this may need to be done more than once a day. This is imperative because humidity can cause moisture to form in the pump and produce sludge in the lubricant, causing premature wear.

While executing daily maintenance is a great way to prolong the life of a compressor, it doesn’t end there. Basic weekly and monthly checks – inspecting the safety relief valve, drive belt tension and checking air connections and compressor joints for leaks – are critical to a machine’s lifespan. Your owner’s manual has more detailed information.

Costly downtime, repairs and the need to purchase a new machine can be mitigated if proper attention is given to an air compressor. They can even last 10-15 years if cared for properly. Treat a compressor like it is a living, breathing thing and it will respond in kind – with years of loyal and reliable service.