Spending a few minutes every day inspecting your inground lifts can lead to greater shop efficiency, increased revenue and less downtime. The latest Rotary Lift “90 Second Know How” video, “Inground Inspection and Maintenance Procedures,” teaches shop managers and technicians proper inground lift daily care and maintenance.

“Properly maintaining your inground lifts is vital to an efficient and profit-producing bay,” says Ron Lainhart, manager of service network excellence for Rotary Lift, and an Automotive Lift Institute (ALI) factory designated trainer. “Sharing this short video with your shop’s managers and techs could mean the difference between preventing a problem and wasting precious time and money fixing it later.”

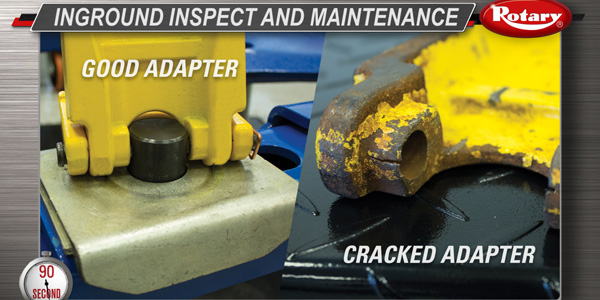

In the video, Lainhart demonstrates daily inground lift inspection steps, including how to make sure the lift controls are in proper working order, ensuring the locks are engaging properly and checking for wear and tear on all the lift structural components.

“Use all your senses when inspecting your lifts,” Lainhart says. “Listen for unusual noises as the lift is being raised and lowered, look for excessive wear on the parts, and feel the plungers to make sure they are properly lubricated.”

In addition to daily lift inspections conducted by technicians, all vehicle lifts also should be inspected at least annually by an ALI Certified Lift Inspector. If repairs are needed, a local Rotary Lift distributor can provide service to get the lift back in service quickly.

Links: