Just in case you might have missed any of our great feature articles from the magazine this year, we have pulled them all together in one spot for you!

There’s much more to come in 2023, so be sure to watch out for TechShop in each issue of ShopOwner magazine and online at TechShopMag.com.

If you have any suggestions for articles or comments, drop us a line at [email protected].

January

Specialty Tools: Problem Solvers, Time Savers and Essentials

Investing in the right ones is an important decision for every technician.

February

Automotive Lifts: A Guide To Lifts And Lifting Equipment Whether you’re replacing one or adding one, buying a lift isn’t a daunting process. Here’s some advice to get you started.

March

Don’t Miss Out On A/C Service Opportunities

Today’s HVAC systems are becoming so advanced, that we could be missing out on service opportunities.

April

It may take a little more planning, but keeping a clean shop is a good move for the industry and good for your business.

May

Even though it’s easy to take for granted, compressed air is the key to many of a shop’s special tools.

June

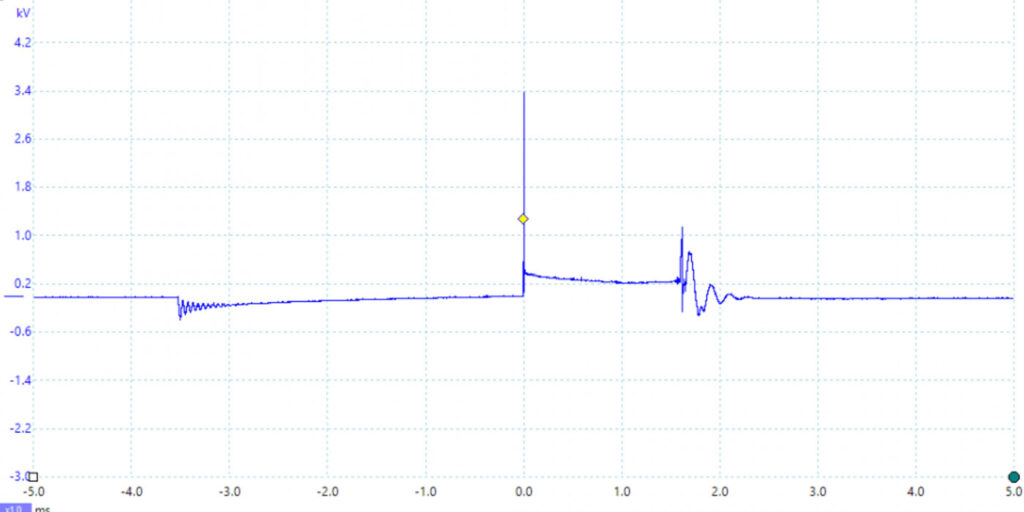

When it comes to investing in an oscilloscope, the biggest question is ROI. Is it going to make you money?

July

The Latest In Auto Repair Workwear

Here’s a look into the many options available in today’s workwear specifically designed for automotive technicians.

August

Automotive Battery and Electrical System Testers

Modern charging system testers are programmed to know what they should see on each and every vehicle.

September

Batteries: Cordless Tools Charge Ahead with Battery Technology

Chemistry defines a battery and modern cordless tools take advantage of the technology to achieve superior performance.

October

Tire & Wheel Service Equipment

Wheels and tires are changing and so is the equipment we use to service them. See how the latest equipment updates stack up.

November

Shop Equipment ROI – Tooled for Profit

If you understand the basic idea and process of calculating ROI, it can help you make good purchasing decisions.

December

Working on the Line – Collision Repair Tools

Equipped with the right tools, technicians can expand their skillset and tackle those jobs that are close to the line between collision and general repair.