“Easy 3D’s innovative technology dramatically improves space efficiency and productivity of automotive service centers,” said David Scribner, Wheel Service Group product manager for Bosch. Bosch plans to start delivering Easy 3D systems to select locations this month.

Through several years of research and development, Bosch engineering developed a new method for determining wheel alignment measurements, Stereoscopic Triangulation. The durable Easy 3D system contains two portable camera pods mounted on an alignment rack with “electronics free” measurement boards attached to each wheel, operating at high speed to enable a 27 Hz update rate, or 27 updates per second.

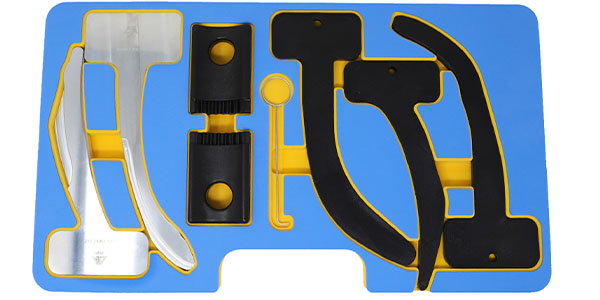

Easy 3D dedicates two cameras to each measurement board for stereoscopic vision of each wheel and an additional two cameras focused under the vehicle, allowing the system to triangulate the position of the wheels in relation to the camera pods. Measurement boards at the wheels and camera pods made from expanded polypropylene with internal suspension damping, contribute to low weight, ease of handling and drop resistance.

Stereoscopic Triangulation, Easy 3D’s innovative measuring method, eliminates the need for calibration during installation, and provides precise measurements that can be repeated even if the camera pods are repositioned in the middle of the alignment process. Easy 3D users can move their system to different bays within the shop where they have two bays dedicated to alignment, or they simply want to move the system to a different bay. Once relocated, Easy 3D utilizes Stereoscopic Triangulation to measure and synchronize the camera pods to the measurement boards at the new location. No calibration is required. Easy 3D’s unique architecture provides the flexibility to work with many different racks. The system can even be used directly on the shop floor for quick alignment audits and for merchandising.

All imaging based alignment systems require some form of compensation procedure to account for wheel runout and measurement of the clamps and boards attached to the wheels. Often, rolling the vehicle to compensate is difficult on larger vehicles. With Easy 3D, the technician may sit in the driver’s seat and complete the entire compensation and alignment measurement process in only a few minutes. The engine running does not affect Easy 3D operation or measurement accuracy. The technician no longer has to push and pull the larger vehicles during the compensation process.

Setting up the Easy 3Dsystem is fast and simple. With its intuitive operation completed in less than seven minutes, just one employee can perform the measurements, allowing faster bay throughput. According to Scribner, Bosch’s intuitive software reduces the need for specialized knowledge in wheel alignment, allowing more technicians to perform alignment service easily.

“We are proud to offer automotive service centers such an advanced tool at a time when their customers are demanding higher quality service,” Scribner said. “With dealership closings and the market realigning, high quality service and customer satisfaction are key success factors for independent automotive service centers. Bosch Easy 3D will help them put their customer’s vehicles back on the road promptly, while improving the quality of service and customer satisfaction.”