Chief Automotive Technologies introduces VelocityMAX, the top-of-the-line computerized frame measuring system that helps collision repair shops make more profit through more accurate damage identification and design-based repairs.

Chief Automotive Technologies introduces VelocityMAX, the top-of-the-line computerized frame measuring system that helps collision repair shops make more profit through more accurate damage identification and design-based repairs.

“VelocityMAX helps shops make more money by revealing hidden damage upfront, so estimators can write more accurate and profitable estimates. It also offers a number of exclusive features that enable technicians to work more efficiently to maximize productivity and profitability,” explains Mike Cranfill, vice president of collision. “Its proprietary software will even help them identify incorrect pull set-ups before they are made, to prevent additional damage and speed up the repair process.”

The heart of VelocityMAX is Chief’s sophisticated Velocity computerized frame measuring system. Velocity uses a laser scanner to provide exact measurements of the entire vehicle for pinpoint accuracy every time. Velocity measures more reference points than any other system and does so simultaneously, so technicians can repair vehicles with diamond or twist damage, as well as frames with both front and rear damage. Velocity is the only system that can measure both strut towers at the same time and can accurately measure engine cradles and cowl hits. Technicians using Velocity can continue measuring in real-time while making repairs, so they don’t waste time measuring after every pull.

Shops using Velocity can print full-color inspection reports showing all vehicle damage before, during and after repairs. These reports document damage and necessary repairs, and prove that the shop returned the vehicle to pre-collision condition. This reinforces trust between the shop and its customers and insurance providers, leading to more repeat and referral business.

All Chief measuring systems offer the company’s exclusive precision vehicle specs. Chief personnel measure every vehicle themselves with the frame anchored and the suspension unloaded in order to provide technicians using Chief systems with “real world” accuracy unmatched by any other source. Chief specs cover more vehicles than any other system available.

The “MAX” in VelocityMAX comes from the wide array of innovative features, software and accessories that transform the standard Velocity into a comprehensive vehicle repair center.

The VelocityMAX comes standard with:

• Intelli-Tape: Record and wirelessly transmit body openings and other point-to-point data to the VelocityMAX system.

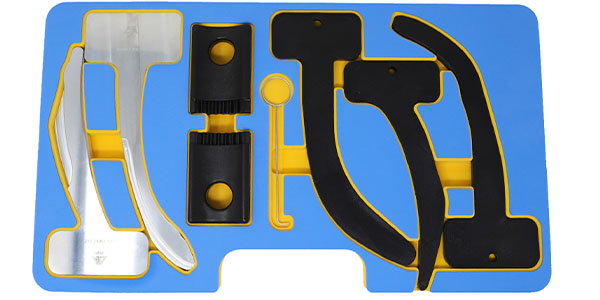

• Rear Wheel Tracking Gauge: Check and verify rear wheel tracking, offset, toe and length from body zero line so technicians can correct alignment issues before reassembly, saving time. Measurements automatically display on the VelocityMAX monitor screen.

• Chief Exclusive E-Access Tech Support: Link directly to the Chief Tech Support team if needed. Chief experts can view the technician’s VelocityMAX monitor and walk him or her through the repair process quickly and accurately and can even assume control of the system, if requested. This exclusive feature also makes it possible to update the shop’s specs regularly.

• Velocity, AutoScan and Estimator Pro-V Software: Easy-to-follow software provides more revenue-generating opportunities and saves time during the front-end inspection and estimating process.

“As vehicles continue to grow in complexity and become increasingly difficult to repair, technicians and shop owners appreciate VelocityMAX’s fast set-up and step-by-step tutorial program that help them make high-quality repairs quickly, accurately and profitably,” says Cranfill.

For more information about VelocityMAX or any of the products in Chief’s full line of measuring systems, structural repair equipment and training, contact your local Chief distributor, call (877) 644-1044 or visit www.chiefautomotive.com.