The CKP (Crankshaft Position Sensor) is one of the basic diesel engine sensors and is necessary for an electronically controlled diesel engine to even start. Let’s have a look at some CKP failures that we have seen.

Ford Transit 2014 2.2 HDi Puma C

This vehicle was presented with a complaint of stalling at idle if left running for a little while. The problem is present during diagnosis; the engine starts well and runs smooth with no evident malfunctions at higher RPM. However, if left at idle, it stalls after a brief while. There is a DTC stored in the PCM (Powertrain Control Module) memory, namely a P0336 (CKP Circuit Range/Performance).

The CKP used on this particular engine configuration is a Hall-effect design. All observed scanner data are nominal with no discernible problems seen. While the engine is stalled, the fuel pressure, as observed, drops slowly, so the problem is not related to a loss of fuel pressure.

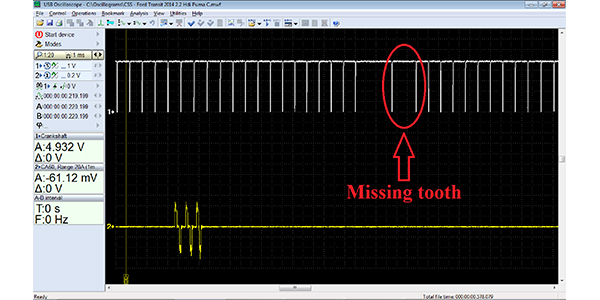

A USB Autoscope is connected to the engine with one channel to an injector and another channel to the CKP sensor. The engine is left running at idle and waveform recording is started.

After just a little while, the engine stalled. Upon careful review of the recording, the following is seen in Figures 1 and 2. One of the markers or teeth is suddenly missing, apparently causing the stall.

The cause of this behavior was an incorrectly installed CKP sensor. Once the air gap was adjusted correctly (adjustable on this particular engine), the problem disappeared. Oddly enough, the engine always started and ran well, the problem would only manifest itself at idle. The PCM did not immediately flag the error either, the engine had to run for a little while.

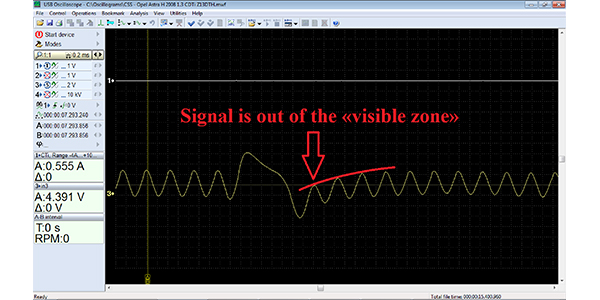

Opel Astra H 2008 1.3 CDTI Z13DTH

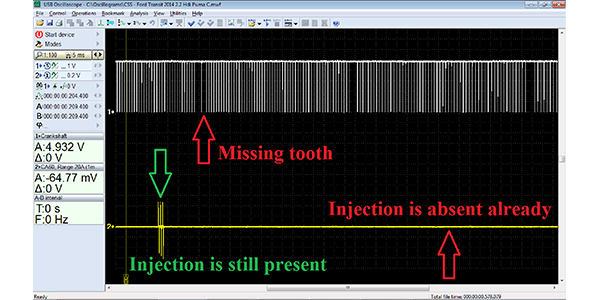

This vehicle came in with the following problem: the engine does not reach target or desired RPM. The problem can occur at different RPMs, such as 1500 or 3000. There are no DTCs, fuel pressure is nominal, it starts well and there is no smoke. No mechanical problems can be found during extensive checking either.

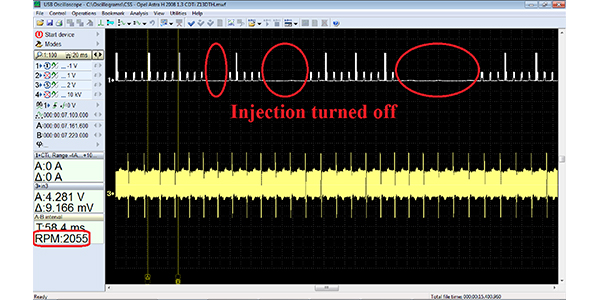

In order to do some integrity testing on the electrical and electronic circuits, a USB Autoscope was connected to the CKP sensor and a current transducer was clamped on the first injector wiring. As can be seen in Figure 3, the problem showed up almost immediately. Figure 4 shows the CKP waveform zoomed in closer and the problem is evident.

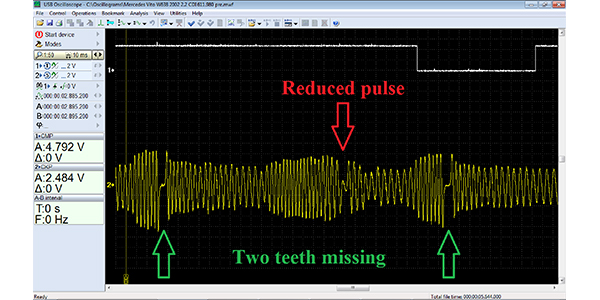

Mercedes Vito W638 2002 2.2 CDI 611.980

After overhaul, the engine will not start. The technician replaced multiple sensors, even a starter. The engine turns over but still won’t start. During diagnostics the following two DTCs were found: P1335 (CKP sensor malfunction) and P1354 (CKP/CMP sync failure).

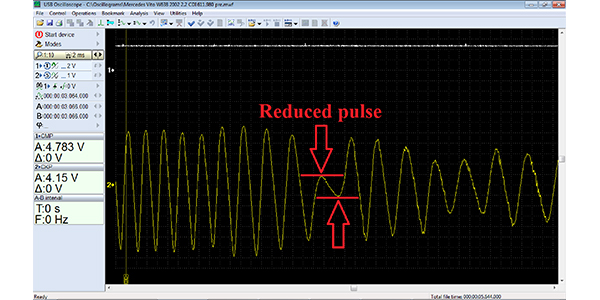

The oscilloscope is connected with one channel to the CKP and one channel to the CMP. The waveform seen in Figure 5 is obtained. Figure 6 shows that what looks like missing teeth are actually the signal with significantly reduced amplitude.

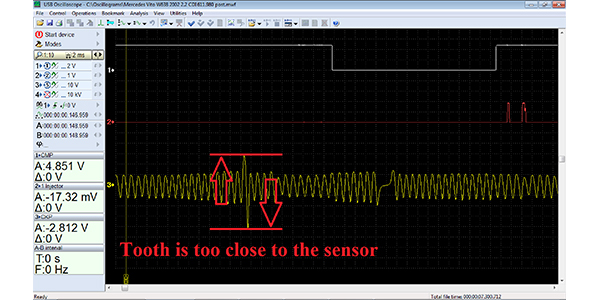

The ECU interprets the low amplitude signal as a tooth pass, and turns off the injection. The cause was a bent tooth on the toothed disk or reluctor. The technician fixed the bent tooth without removing the transmission. Finally, the car starts. However, Figure 7 shows that the technician was overzealous, slightly overdid it and bent the tooth too far the other way.