Direct injection is becoming standard on more and more late-model vehicles. These systems can be a diagnostic challenge but, with the right foundation, problems can be solved profitably.

Years ago, all an entry-level technician needed to diagnose a fuel problem was a set of “noid lights,” a fuel pressure gauge and maybe a meter. These tools can’t be used on direct-injection systems because of higher pressures and changes in the injector location and technology. Voltages from the injector drivers can range anywhere from 30-120 volts depending on the system, and pressures can go as high as 2,300 psi. The go-to tool for direct injection will be a scan tool that can look at special direct fuel injection parameters and perform bi-directional tests.

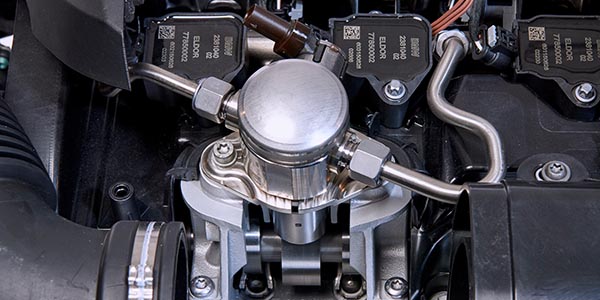

Some of the tests are the same, such as the injector balance and load testing, but more insight is needed into how the placement of the injector and the high-pressure fuel pump play into driveability diagnostics…

To continue reading, click here.