Now that we know how electricity works and how to do some basic tests, let’s look at how electrical circuits are protected and controlled.

The electrical system must pass current from the power source (battery and/or alternator) to the load device. To do this in a safe manner, all electrical circuits are protected from overload in case they try to pass too much current. Most often this protection is done with some type of fuse, however, engineers can also utilize circuit breakers and PTCs to help protect a given circuit. Before we look at these three types of circuit protection, let’s discuss why we need to protect the circuit in the first place.

First, we must remember that electricity can only give itself up as heat. The more current that passes through a circuit the more heat we produce. When an engineer designs a circuit (s)he knows how much current the load device will use.

For example, when I turn the parking lamps on in my 2011 Malibu, I’m turning on nine bulbs. Since these bulbs are wired together in parallel, the current from each branch (bulb) is added together to give me my total circuit amperage. Since it adds up to about 6 amps, the engineer uses a 10-amp fuse to protect it. If one of the bulbs burns out, the circuit amperage would drop. However, if this circuit were to experience a short to ground, this would add a low-resistance path to ground for current to flow, thus raising the amount of total circuit amperage. This increase in amperage would cause the fuse to “blow,” creating an open in the circuit and stopping the flow of current.

This is critical for all electrical systems since the size of the wiring, switch and connectors are based on the nine bulbs together pulling less than 10 amps. If the fuse were not in the circuit to protect it, the wires, switches or connectors could heat up and cause a fire. So why does the fuse blow before wires melt? Simple, the wire in the fuse is designed to be the “weak link” in the electrical chain.

In the case of my Malibu lights, the fuse is designed to melt from the heat created by current flow when the current exceeds its rating of 10 amps. The rest of the circuit would be designed to handle a little more current/heat than the fuse. This is why we never install a fuse that is larger than what the circuit is designed for. If a 20-amp fuse was installed into a 10-amp circuit and that circuit experienced a short to ground, the fuse may no longer be the weak link, resulting in the wire melting from the heat of current flow and not the fuse.

Fuses

There are a variety of fuses used today and they all perform the same function, but they may look different. Figure 1 shows several different types of push-in plastic fuses. When the auto industry moved away from the old glass tube fuse in the ’70s and early ’80s to the plastic push-in fuse, we first saw the use of the ATC/ATO fuse. The ATC fuse is the most common because it is closed on the bottom (hence the “C” in ATC) and the ATO fuse is open on the bottom (hence the “O” in ATO), exposing the element to the environment and increasing the chance of corrosion. This was quickly referred to as a “regular” fuse.

As the electrical requirements of vehicles continued to increase so did the size of the fuse panels. Up until the mid to late ’70s, one fuse panel under the dash would support the entire vehicle. Today’s modern vehicles have two or three fuse boxes to support all of their electrical circuits — and these fuse boxes are crowded. Because of this, the industry went to a “mini” fuse that is about one-half the size of a regular push-in fuse. Some vehicles today even utilize a “micro” fuse for more space savings. A load needing a large amount of current may get a maxi fuse or a Pacific fuse. Regardless of the shape or size of the fuse, they all work the same.

Fusible Links

Another type of fuse used on older as well as some of today’s vehicles is the fusible link. A fusible link works the same way as a fuse except the wire that is the fuse is located inside the sheathing of the fusible link wire and cannot be seen. Fusible links are also part of the wiring harness, so if one blows it must be cut out and a new one spliced in.

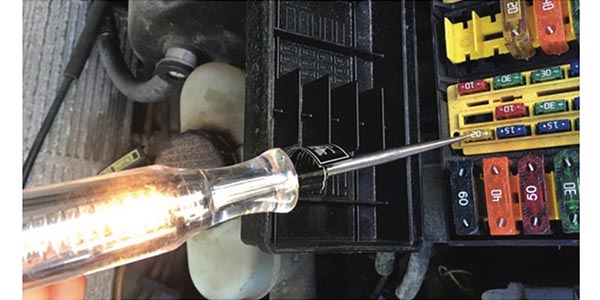

Fuses and fusible links are tested in very similar ways. Since a fuse/fusible link takes power in one side and delivers it out the other, we simply have to check and see if the fuse/fusible link has power on both sides. For a push-in fuse this is very easy, you simply take a test light and touch the terminal sticking out on the top of the fuse and it should light on both sides of the fuse. This can be easily done without removing the fuse. If the fuse does not light on both sides it simply means that the key must be turned on prior to testing or the component protected by that fuse must first be turned on. Regardless where the key position is, once you have power on one side of the fuse you should have power on the other.

Fusible links are tested the same way, except gaining access to both sides of the link can be more difficult. Sometimes one end of the link can be traced back to the fuse block or component it gets its power from. However, sometimes the link is in the middle of the harness and neither end can be accessed easily. In these situations I will pierce the link with my test light or piercing tool to check for power. If I have power at both sides I will put a dab of liquid tape over the hole in the insulation to prevent corrosion.

Circuit Breakers

Another device used to protect a circuit is called a circuit breaker (AKA breaker). The breaker in a vehicle will be rated to handle a certain amount of current; if the circuit tries to pass more current than it is rated for, the breaker will get too hot and open up, disconnecting the load from the power source. When the breaker cools, it will automatically close. Most circuit breakers are in a metal container and are larger than a regular ATC fuse but push into the fuse block just like a fuse does.

Usually the only components protected with a circuit breaker are those that contain an electric motor and have a start and stop position like the wipers or a power window. Many of today’s circuits that require protection from a breaker will have the breaker built into the load so the technician will never see it except on a wiring diagram. To test a circuit breaker in a fuse block, simply pull the breaker out and ohm test it. A good breaker will have less than 0.2 ohms of resistance.

Positive Temperature Coefficient

The last form of circuit protection we’ll discuss is the positive temperature coefficient thermistor or PTC. A PTC is usually a silicon-based device whose resistance changes based on heat. When a PTC heats up, its resistance goes up dramatically and when it cools, its resistance goes back down. In essence, it works much like a circuit breaker, which is why engineers often use a PTC in place of a circuit breaker.

If a PTC is used on an automotive circuit, it is always built into the load device (a power window motor for example) and is never seen by the technician. In this case, if a power window motor stopped working, you may never know if the PTC failed or the motor failed; since the PTC is built into the motor, the whole unit is replaced.