By Matt Roda, Associate Professor, Automotive Technology, Mott Community College, Flint, MI

In my 30+ years as a technician and automotive educator, I’ve seen way too many techs shy away from electrical work simply because they didn’t understand it. Most of these techs end up doing undercar work because there is lots of it and you can usually avoid dealing with electricity, or they manage to fix an electrical problem but aren’t sure how they did it. With anti-lock brakes, stability control, electric power steering and other such items invading the undercar world, I think it’s safe to say there is nowhere to hide anymore if you don’t want to deal with electricity. In this five-part series on electricity, I’d like to help alleviate any anxiety and misconceptions you may have about electricity and have you tackling that electrical work like the pro you are.

Break It Down

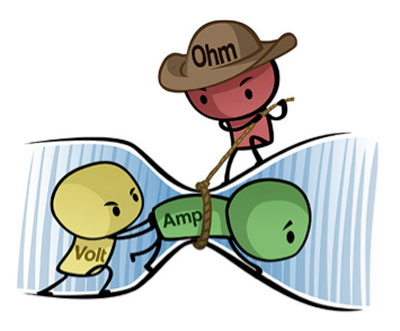

We’ll start by breaking electricity down into three parts: Volts, Amps and Resistance (Ohms).

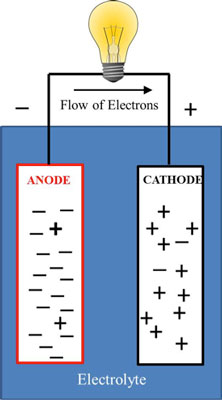

Voltage (volts) is the pressure that pushes the amperage through the circuit. It is created by having a “potential difference” on both sides of a cell. The greater the “potential difference” is, the more voltage you have in a cell (see Figure 1). If there is no potential difference on the sides of the cell then there is no voltage to push the electrons through the wire. In the automotive business we call this a dead battery.

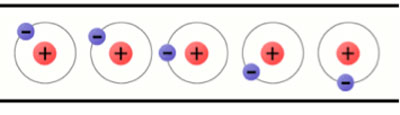

Amperage (amps) is the movement of electrons from one atom to another across a conductor, also referred to as current flow. These moving electrons are forced across a conductor by voltage and these electrons are what perform the work in a circuit (see Figure 2).

Resistance (which is measured in Ohms) will restrict the flow of amperage. As resistance increases in a circuit, the current flow will decrease in that circuit, if resistance decreases, current flow will increase (see Figure 3).

In automotive circuits, we need the amperage to make something work yet amperage will only flow if we have enough voltage to make it flow and no unwanted resistance stopping the current from flowing. The effect that volts, amps and resistance have on each other is called Ohm’s Law. Ohm’s Law states it takes 1 volt to push 1 amp through 1 Ohm of resistance; in simpler terms, volts divided by Ohms equals amps.

Figuring a car battery has 12 volts and a lighting circuit has 2 ohms of resistance, then 6 amps of current will flow in this circuit (12/2=6). In an automotive wiring circuit there are only two things that can change the flow of current in a circuit: voltage going up or down and resistance going up or down. Since the voltage in a running vehicle’s electrical system is usually between 13.5 and 15 volts, with a properly working battery and alternator, the main cause of most electrical problems is unwanted resistance. All electrical systems are engineered with a specific amount of resistance, but if this resistance goes up or down, that’s when problems occur.

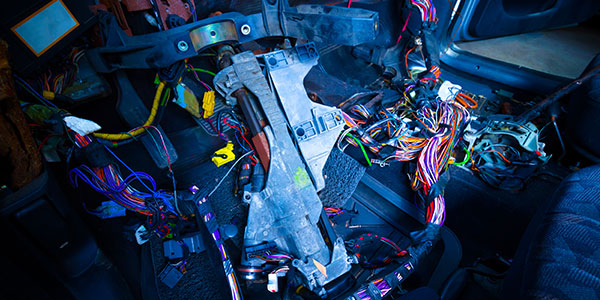

There are five things that can create resistance in any circuit: the length of a conductor, the diameter of a conductor, the type of conductor (metal, copper, etc.), heat and the quality of a connection. The first four are engineered into a circuit and rarely change, therefore most of our automotive electrical issues are a “quality of connection” issue. This condition will present itself in the form of rust, corrosion, loose or ill-fitting terminals in a connector and broken or loose wires.

Think about a lighting circuit that has 0.5 Ohms of resistance built into it, 12/0.5=24 amps of current flow. If the ground screw rusts enough to add an additional 0.5 Ohms of resistance, the circuit now has a total resistance of 1 Ohm, 12/1=12 amps. The lights will illuminate with 12 amps but will be dimmer than they are designed to be with 24 amps. If the same ground wire is broken, the resistance will be so high that no amps can flow, therefore the lights won’t work. This is referred to as an “open circuit.” Since excessive resistance and open circuits make up most of our electrical issues in a vehicle, the more you understand about them, the better equipped you are to make the needed repair.