Hunter’s popular AutoComp Elite (ACE) on-car brake lathe with tablet now also connects with the HunterNet 2 platform.

HunterNet 2 is a free customer portal developed for undercar service operators with single or multiple rooftops, allowing operators to access actionable performance data for all their Hunter-connected equipment.

With the new connectivity and the optional DigiCal feature, shop owners and managers will be able to view before and after cut results for rotors online, before and after runout, plus monitor lathe usage counts and track equipment ROI. They’ll also be able to order consumables 24/7 and access the online user manual.

The easily accessible before-and-after data will provide valuable documentation for warranty purposes, as well as transparency for customers.

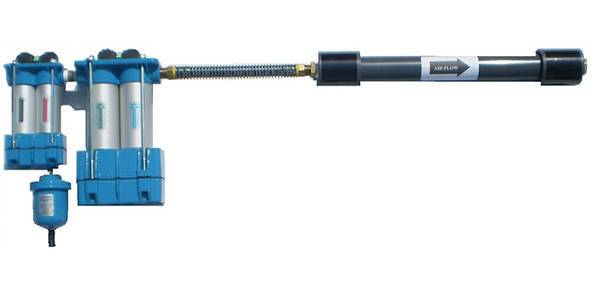

The ACE lathe features a patented variable-speed drive system and anti-chatter technology to service rotors at the fastest possible speed without sacrificing quality. The technology virtually eliminates the buildup of vibration that can occur when machining rotors at a fixed speed.

The tablet conveniently brings a wide range of information to the technician’s fingertips in an intuitive, user-friendly display.

Previously, to find the rotor’s minimum thickness or maximum drum diameter, the technician had to search for it on the part itself. With the new tablet, the operator can look up the vehicle and access the specifications immediately.

The tablet then calculates the distance between the cutting bits on the lathe and compares it live to the specifications. When the bits move beyond the specs, the screen turns red. When they stay within, the screen remains green.

For more information, visit https://www.hunter.com/brake-lathes/autocomp-elite.