By Olle Gladso and Sergey Gazetin

Contributing Writers and Instructors at Riverland Technical and Community College in Albert Lea, MN

This particular vehicle took up a lot of time. Not because the problem was difficult, but rather because the problem was intermittent and the customer didn’t want to spend money unless the diagnosis was certain. Because the problem was intermittent, it was very difficult to arrive at a 100% diagnosis. The best I could do for a long period of time was an educated guess.

The vehicle is a 2008 Hyundai Santa Fe equipped with a D 2.2 – TCI – D diesel engine, which has a displacement of 2.2 liters.

This vehicle was brought to us with a complaint of intermittently losing power and throttle response. If the engine was turned off and restarted, the problem would disappear and it could be quite a while before the issue reoccurred. The vehicle had been to other shops, but no firm diagnosis could be found. A Hyundai dealer had suggested that the problem was with the turbo, but, again, no firm diagnosis.

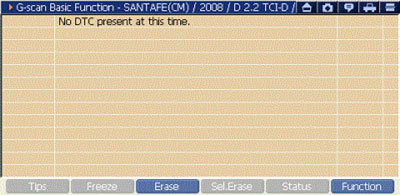

In addition to the problem being very intermittent, no DTCs have set. See Figure 1.

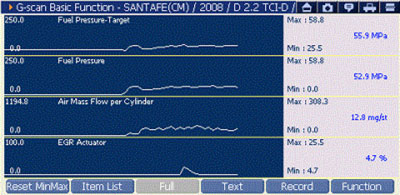

All data parameters as seen on the scan tool were within normal ranges. Based on the symptoms as described by the customer, we suggested that the most likely cause is an intermittently malfunctioning EGR valve. We explained to him that since he wanted us to be absolutely sure in our diagnosis before he agreed to pay us, the problem had to be present and observable. We also explained that since the concern is so intermittent, the vehicle would have to be driven with diagnostic equipment hooked up until the problem is present and observable. The vehicle owner understood and agreed to drive the vehicle with a scan tool connected until the problem would manifest. I connected a G-Scan to the diagnostic connector, activated the graphics mode, as can be seen in Figure 2, and the customer drove off. This first trip, even though it lasted well over an hour, had no malfunctions. We gave up, at least for the time being.

Several months later, in the beginning of April, the owner called and said that with the first relatively warm and damp days, the problem appeared again. For a few minutes, at every cold start, the problem again was present.

The customer dropped the vehicle off for us to keep until we could come up with a reason for the problem. The next morning the vehicle was driven, and just a few miles down the road the malfunction was present. And was it ever present! After a couple of accelerations and braking at different speeds, the engine suddenly stalled. It was hard to restart and the idle quality was very poor with multiple misfires. Depressing the accelerator pedal had almost no effect. Shutting the vehicle off and restarting it didn’t alleviate the problem. Obviously, whatever was wrong had gotten significantly worse. Since the malfunction was present, a firm diagnosis should be much easier to accomplish.

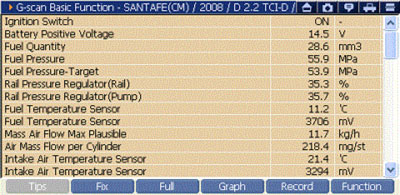

Since it was a test drive, the scan tool was connected and all that was left to do was to carefully analyze the parameters in the data stream. The ECU didn’t store any error codes, as in the past. What did we find then? Firstly, the fuel pressure in the rail is OK. As can be seen from the data present in Figure 3, the value of the preset pressure is 53.9 MPa, i.e. 539 Bar, and the real pressure value is 55.9 MPa, i.e. 559 Bar. Even without taking into account the time delay when streaming the different data to a scan tool, the difference is so small so as to be insignificant. The fuel system is operating as intended.

One thing that stands out as a major concern is the very low airflow indication given in the data. The airflow is listed as 11.3 kg/h (24.9 lb./h). The data stream also shows each cylinder’s fill per cycle, given as 218 mg/cycle (0.008 oz./cycle). The EGR duty cycle is only 4.7%, so the EGR valve should not be the cause of low air consumption, being that it should be closed. However, a slightly open EGR valve would explain the low cylinder fill and likely also the misfires. The data stream does not indicate anything out of the ordinary with the EGR valve.

It is noted that there are no data related to the valve’s position, but the symptoms would certainly indicate a slightly open valve. The vehicle is emitting white exhaust, indicating unburned diesel coming out of the tail pipe.

Figure 4 shows the EGR valve. Figure 5 shows the disconnected connector with only two wires going to the valve. Since there are only two wires, there is no valve position sensor. The lack of a sensor explains why there are no trouble codes in the ECU for a stuck open EGR valve. The ECU simply does not know the valve position.

Figures 6, 7 and 8 show the process used to verify that the valve was, in fact, stuck slightly open. The opening is not very evident by just looking at the valve, so an external light source was used. The light shining through the valve as shown in Figure 8 clearly gives evidence to our suspicion.

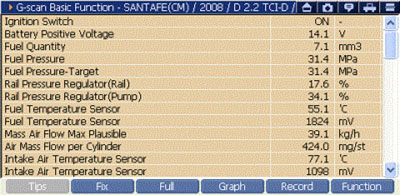

The installation of a new valve shown in Figure 9 solved the problem. Figure 10 shows the scan tool data taken from the same engine, now with a new valve installed.

This vehicle has 130,000 km (almost 81,000 miles), so it is anybody’s guess as to when something else will break, requiring more diagnosis and repair.