When a customer pays cash for an A/C repair, what do you give them? Climate Change! Don’t worry, I’m keeping my day job. And today, my job is writing about air conditioning tools. But you’ve heard this before, right? You get it. Recovery and recycling machines, refrigerant identifiers, dye injectors, ultraviolet lights, electronic leak detectors…the list goes on. The refrigerants change, but the equipment remains the same. Or does it?

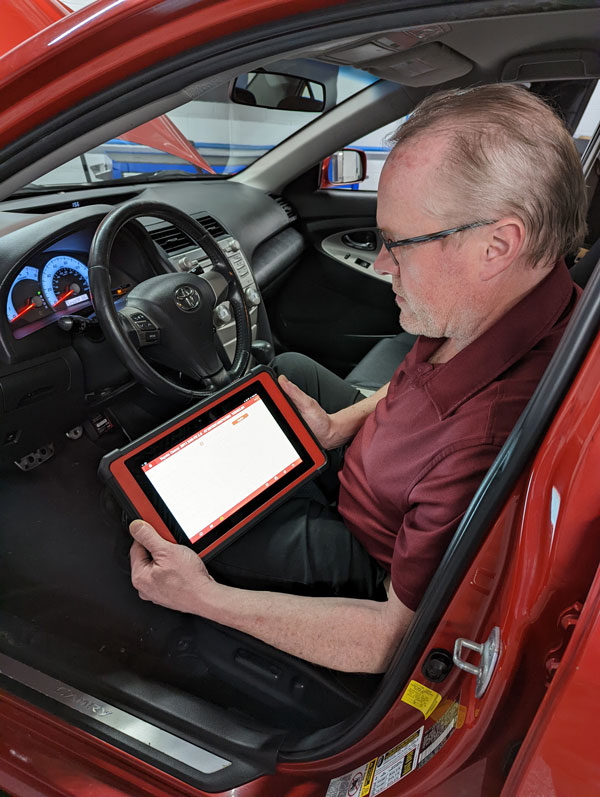

Is there a forgotten tool? One you can’t live without? Here’s a hint: You use it every day. It’s expensive. Have you guessed yet? It’s your scan tool. No, this is not a revelation. We all know that some climate control systems are loaded with electronic control and can store trouble codes. But a scan tool is often overlooked, and often the last thing that comes to mind — but that could be changing.

Traditionally, if an air conditioning system is not working properly, the first thing you do is put a thermometer in one of the air outlets, turn it on max and see what happens. You look and listen to see how the compressor is operating, if the radiator cooling fan is running and if the recirculation door is working properly. This is your first step to confirming the complaint.

Depending on what happens, you may suspect or determine that the system is low on refrigerant. Even if the compressor seems to run fine, we still know that with the low volume of refrigerant required in today’s cars, it doesn’t take much of a leak to create a problem. It’s a common practice to perform a standard evac and recharge, just to confirm the correct refrigerant charge.

Sometimes a car will come and go, and we may find and fix a leak or another obvious problem with the A/C system, without ever communicating with the HVAC control module. I’ve been guilty of it many times, and if the air conditioning seems to be cooling normally, the customer is happy, right? Usually, they are. They just want the system to work. But we could be missing out on other opportunities for service that could not only be profitable for us but would also improve system performance and demonstrate a commitment of quality to our customers.

It’s possible that we don’t always check for HVAC codes because there’s no annoying orange light that glows on the dash. It’s simply easy to overlook. Today’s HVAC systems are becoming so advanced that we could be missing out on opportunities, and at minimum, if we take the time to connect to the HVAC control module, check for trouble codes and look at the data, we are learning and familiarizing ourselves with what normal operation looks like. And that can only benefit our diagnostic process in the future.

Here’s a look at some features of a typical electronic HVAC system today. HVAC control modules maintain the desired interior temperature, fan speed and air distribution as requested by the driver. There are many components that are controlled or utilized for information, including door actuators, the blower motor, evaporator temperature sensors, duct temperature sensors, A/C refrigerant pressure sensor, A/C compressor, ambient light sensor, windshield and inside moisture sensors.

Door actuators are typically stepper motors that operate off a 12V reference and pulsed ground signals from the control unit. These motors are found on outlet mode and temperature blend doors, as well as the recirculation door. They need to be calibrated to their position when new, so the control unit is able to recognize them in their correct positions.

Blower motors are rarely the simple switch-resistor circuits of the past; it’s more likely they operate by receiving a pulse width modulated (PWM) signal that the control module sends to the integrated circuitry of the motor.

Evaporator temperature is sent to the control unit. A common sensor type is a negative temperature coefficient thermistor installed near the evaporator core that measures the air temperature as it exits the evaporator. Based on driver settings, HVAC programming logic will determine a target evaporator air temperature and operate the compressor as needed to reach that temperature.

Duct temperature sensors are another common feature of HVAC systems that improves their accuracy. They measure the temperature of the air flowing through the ducts and the control unit uses the values to calculate the blend door position.

All systems have an A/C refrigerant pressure sensor to prevent the compressor from running if the refrigerant is too low. As opposed to a two-wire pressure sensor in the compressor clutch relay power circuit, as was common, it’s more likely you will see a piezoelectric pressure transducer operating off a 5V reference signal. This type of sensor will send a varying voltage signal to the control module, depending on system pressure, and the control module will in turn control the compressor clutch engagement.

A/C compressors used to be simple. They ran or they didn’t. Not anymore. Today, you may see a variable displacement solenoid valve that changes the amount of displacement produced by the compressor when it is running, controlled by a PWM ground signal.

Ambient light sensors are often now referred to as sunload sensors or solar sensors. They measure the intensity of the sun, allowing the control unit to compensate for it. They often also measure interior temperature.

Windshield temperature and inside moisture sensors are another newer aspect of A/C control, and they transmit information to the control unit about the relative humidity level at the windshield, temperature of the windshield and temperature of the humidity sensor element. The control unit factors that information to calculate fog risk and therefore reduce fuel consumption by decreasing A/C compressor power to a minimum level without allowing fog.

In defrost mode, we’re used to the recirculation door being wide open to fresh air to prevent moisture buildup on the windshield. Now, with the use of humidity sensors, the control unit is able to partially recirculate the interior air to speed the heat-up of the interior in very cold conditions without risking moisture buildup on the windshield.

Another operational feature of some HVAC systems is after-run of the blower fan. With this feature, the blower fan continues to run after the engine is turned off. This reduces the amount of bacterial growth on the evaporator core, which can cause unpleasant odors. Some vehicles are equipped with this feature, but it is not enabled when the vehicle is new. If the feature is present, it can be enabled with your scan tool.

Do you have a vehicle with a start/stop system? If so, you’ve got a heater coolant pump that circulates coolant through the heater core when the engine is not running. Its operation is based on ambient temperature.

Is it safe to say HVAC is a little more complex than it used to be? Absolutely. There was a time when we dove into drivability diagnostics before even thinking about looking for trouble codes or connecting a scan tool. After all, what does that scan tool know? Now, even if we see something obvious, we don’t move forward until we’ve checked trouble codes, looked at monitors and viewed basic engine data.

When we do the same with an HVAC complaint, we are going to get the whole picture, as well as an immediate idea of the systems that a vehicle is equipped with. Many manufacturers use different terminology for their components and their operation and control can differ as well. A quick look with a scan tool will start out the diagnostic process on the right path.

“The climate of HVAC work has changed – and changed for good.”

The time of HVAC is here. Even though there’s no glowing orange light on the dash, we need to look at the data for our benefit and for our customers. The climate of HVAC work has changed – and changed for good. TS