Many jobs require special tools. Sometimes you absolutely need them, and sometimes you can get away without. The buying decision involves multiple factors: How expensive is the tool, how often will you do the job, how hard is it without the special tools and is quality affected adversely if you don’t use them?

Often the question is answered by doing a job once, maybe getting it done successfully, but deciding you won’t do it again without the special tools. One of those jobs for me is fuel line repair, either repairing nylon lines or replacing rusted metal lines with nylon.

There are only a few special tools that come into play, but they work so well they almost make the job fun. The first one you’ll always use is a special cutter for the nylon tube. It’s like a custom-made razor knife, but it makes a clean cut, leaving no pinching or burrs.

Any work with nylon fuel lines is simple in nature and comes down to measuring the line, cutting it, and installing the end fittings, but installing the end fittings can be the tough part. Without the proper tools, way too many times I’ve found myself warming the end of the nylon tube in hot water, then trying to push a fitting in by hand. It works, almost, but it’s not easy. I say almost because I’ve kinked plenty of lines and had to start over, and the best I’ve ever done is getting a fitting in 80% of the way, but not having the strength or grip on the line to go the rest of the way.

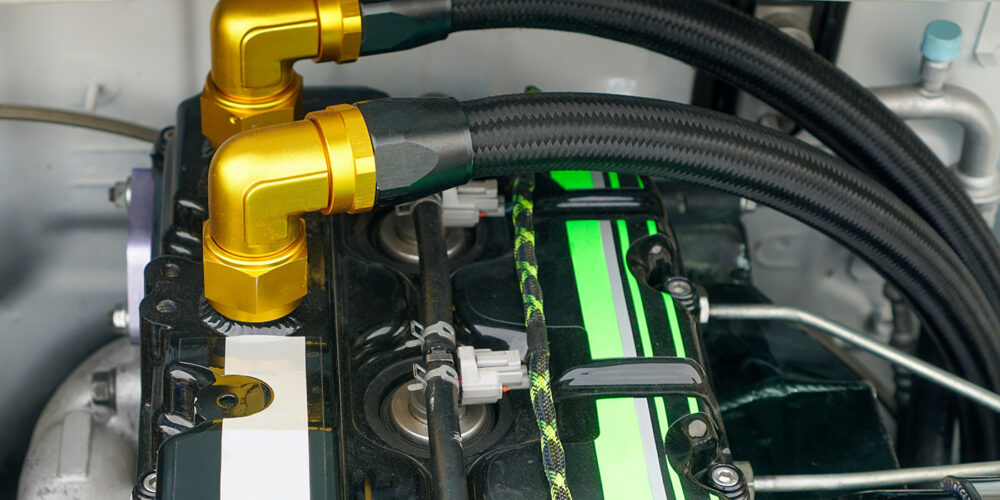

Now I have all the special tools, and I love this work. My favorite tool for this job is called a hose press or a hose assembly press, and there are multiple different ones available. These are designed for bench operation for installing any type of hose fitting into hose. What makes them work so efficiently for nylon fuel lines is adapters that allow you to clamp the nylon line in the vise on one end and use multiple jaw options to hold the fitting you are working with in the other. With both pieces clamped in place, rotating a screw between the two vises draws them together, and the nylon line is effortlessly pushed onto the fitting.

Of course, sometimes you’re doing a repair on the car, but there’s a variation that makes this just as easy. There’s a handheld tool that performs the same job as a hose press but works similar to a caulking gun. It’s not as convenient overall as the press, but it allows you to do a repair on the vehicle.

Finally, there’s a special tool for the mini crimp-clamps that finish the installation. For fuel line repair, I answered the questions easily. The tools weren’t that expensive, and even though I don’t do it all the time, it’s absolutely no fun without them and quality can be adversely affected. Quality is number one with me. Bring on the fuel lines. TS