Maintaining the proper levels of inflation in a vehicle’s tires is crucial to keep drivers safe and the vehicle fuel-efficient. But there’s another, often overlooked reason tire inflation inspections should always be top of mind when servicing any vehicle that comes into your bays: protecting the tire bead.

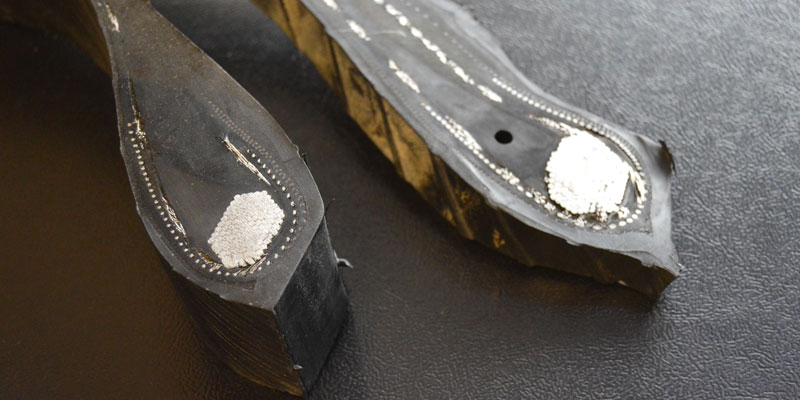

The tire bead is an integral component of any tire, and it can be found at the tire’s inner circle where it connects to the wheel rim. The bead is made of heavy-duty rubber, fabrics and high-tensile wound steel cables called bead bundles. Two bead bundles can be found in every tire — one on the inner side and one on the outer side.

The main purpose of the bead is to keep the tire connected to the wheel, said Phil Mosier, Cooper Tire & Rubber Co.’s manager of commercial tire development, and all traditional passenger and commercial tires are designed with this component.

“The tire bead is a critical component of the tire — it helps securely fit the tire to the rim and seals in the inflation pressure so it doesn’t leak from the tire/rim interface,” Mosier explained. “Functionally, the bead also serves as the anchor to secure the tire to the rim. The inflation pressure inside of the tire exerts tension on the tire’s body ply — the body ply wraps around the bead in the lower sidewall of the tire. Thus, the bead is helping to restrain that tension from the body ply.”

While there are multiple ways a technician could mount or dismount a tire, one of the best methods for protecting the tire bead is to use a tire changer. Both heavy-duty and standard tire changers aid in the removal and installation of tires onto wheels, but they achieve this in different ways, according to Kyle Harris, a product marketing manager for Hennessy Industries, which manufactures Coats tire changers and wheel balancers.

Heavy-duty tire changers are generally hydraulic-powered and use either a hook or rollers to mount and demount tires. They also typically incorporate a lifting mechanism, as heavy-duty truck wheels weigh hundreds of pounds, Harris says. While standard tire changers work in a similar way, most utilize a bar and a duckbill to mount and demount tires and are electric- and air-powered.

While the tire bead is designed to withstand high loads and immense pressure, technicians need to be patient throughout the tire mounting process to avoid inadvertent damage to the bead, as well as keep themselves out of harm’s way, Harris added.

“One of the most important safety tips regarding beads is to always verify correct tire and wheel sizing, and never try to mount a tire on an incorrect or damaged wheel. Most commonly, technicians might not have the bead in the proper position during demounting or mounting of the top bead. This can stress or break the cables that make up the bead,” Harris said. “And, most importantly, always wear proper safety gear and utilize an inflation cage when [inflating the tires].”

Pete Liebetreu, vice president of marketing for Hunter Engineering, which manufactures a variety of tire service machines, added that keeping technicians safe when mounting tires comes down to minimizing mounting stress.

“Use care, and use quality lubrication,” Liebetreu advised. “Use professional equipment with sophisticated mount heads and press devices that minimize mounting stress, which can damage beads. Never inflate a torn bead; it can be extremely dangerous. Always use a safety cage for commercial tires and any passenger car tire over 40 psi.”

Echoing Liebetreu, Harris added one of the most common ways a technician might inadvertently damage the tire bead is from not using enough lubrication on the bead when mounting or dismounting tires. He said it’s good to remember that any routine tire service that’s good for the tire is also good for the bead, including regularly rotating, balancing, aligning and, most importantly, maintaining proper pressure.

While commercial tire beads are typically built using more robust materials to handle the higher loads and heat the truck’s components generate on the road, Rob Williams, senior director of TBR sales for Hankook Tire America, said regular maintenance, including routine pre- and post-trip tire inflation inspections by drivers, is especially critical to keeping the bead intact.

“Since the bead section is directly in contact with the rim, it is easily affected by heat generated from the rim, overloading, low air pressure, etc. In the context of commercial, overloading a tire via weight or road-generated heat at the bead site [increases] the risk of hardening the tire and ultimately reduces the lifetime of that area, [thus] increasing the risk of deformation/failure of the tire and rim assembly,” he said. “In both cases, lack of maintenance can result in a tire burst or separation from the rim (de-bead).”