The Story of U0100

This article will document Code U0100 — Lost Communication with the ECM/PCM.

In the world of automotive module-to-module communication, it can mimic a good guy/bad guy situation — the good guy has made an attempt to communicate with the bad guy and the bad guy does not respond. The good guy will then report to whoever will listen via a U-code that the bad guy is not talking. So keep in mind that the module storing the U-code is in many cases the good guy.

This issue’s diagnostic journey begins with a 2010 Chrysler Town & Country. The vehicle has been taken in for an emission test and has failed to communicate with the state’s equipment. Not by any means is the failure to communicate issue unique, however, this vehicle has a unique signature to it in terms of what it does when it attempts to communicate: the wipers will sweep once across the windshield and the headlamps will illuminate once and then turn off.

In many cases, but not all, the comment “U-code, not me code” holds true. This vehicle was scanned using several generic scan tools as well as the manufacturer’s scan tool. We were able to obtain scan data with both tools, but keep in mind that in order to pass the emissions test, the vehicle must pass on the state’s equipment. I will attempt with the following pictorials to outline the series of events as they unfolded.

The first pictorial, Figure 1, shows the vehicle’s reaction to being scanned.

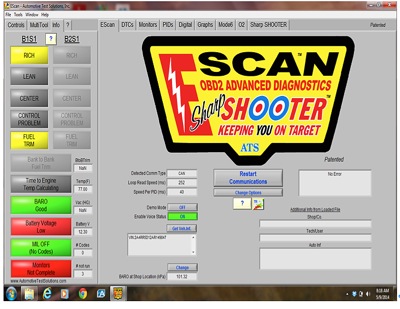

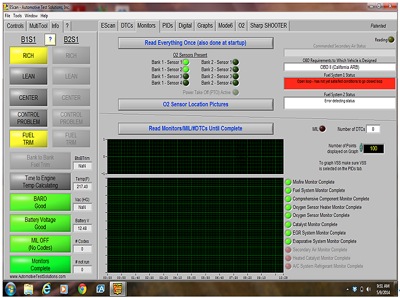

You can see the wipers doing a sweep across the windshield. The headlamps also illuminated once. The next step was to try a generic scan tool (Escan) to see if we could communicate with this vehicle. Figures 2 and 3 show that we were able to communicate and that all monitors ran and passed.

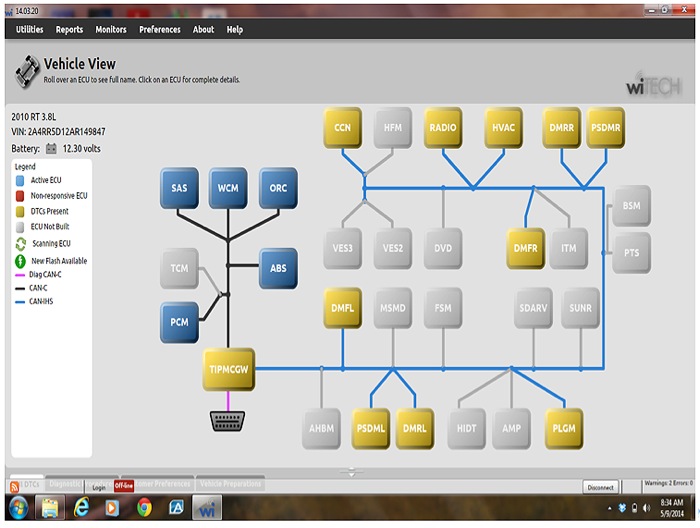

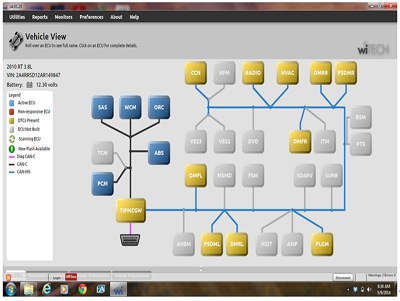

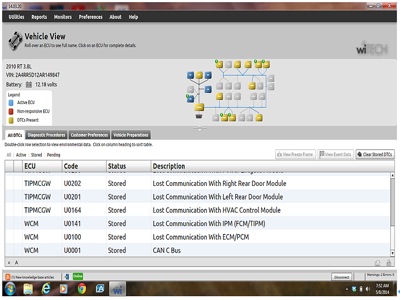

The communication architecture of this vehicle is quite interesting. There is a central gateway called the TIPM (Totally Integrated Power Module) that the scan tool must first go through in order to speak to the PCM as well as other modules (ABS, ORC, WCM, etc.), which reside on CAN C. A series of other modules (CCN, HVAC, radio, etc.) are on the CAN B line. The WiTECH scan tool used by the Chrysler dealer was employed to look at the system. The topology screen in Figure 4 shows a layout of the modules for this vehicle, prior to looking at codes. The codes were then reviewed and the system showed we had a series of U-codes, see Figure 5, which denotes these codes.

It appears that the WCM (wireless control module) is the one setting the codes that we have the most interest in. The two codes are U0100 (Lost Communication with ECM/PCM) and U0001 (CAN C issue). This information implies that there may be a communication issue with the CAN C line causing us not to be able to communicate with the PCM.

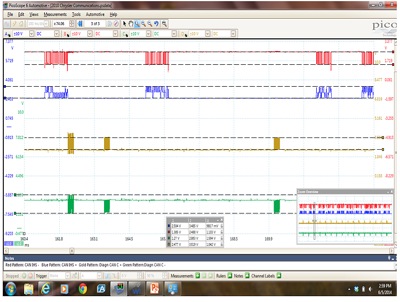

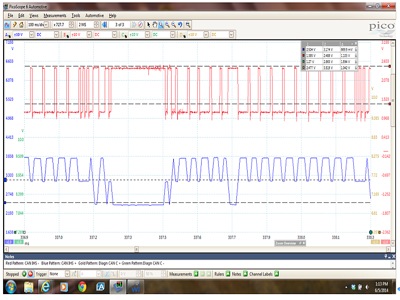

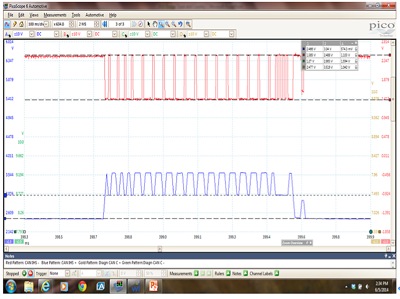

It’s now time to use our PicoScope to determine where the fault maybe hiding. The following pictorials, Figures 6-9, show what was witnessed on this vehicle.

The CAN C line appears to be fine, but the CAN B line has an issue. Note for reference that there were several codes indicating an issue with CAN B as well. The PicoScope was used to look at CAN C, Diagnostic CAN C and CAN B. The only one that did not pass the test was CAN B as shown in Figure 7.

There have been some cases where issues with other communication lines via the gateway may cause issues with communication per the PCM. They are rare, but do exist.

We attempted to repair the CAN B line to see if this would allow us to communicate with the PCM. A short time later, the vehicle failed to communicate at all and a topology screen now showed that the TIPM was not talking. The TIPM was replaced as a result of this.

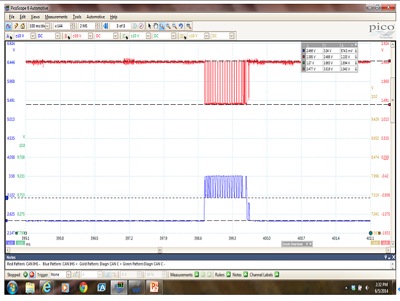

After the TIPM was replaced, the vehicle was scanned again and it showed that there was still an issue with the CAN B line. All of the modules were taken off the bus and the CAN B line was checked at the TIPM with the communication line disconnected from the TIPM. The CAN B line was still at fault.

In our final pictorial, Figure 9, we attempted to make a final analysis of this failure, the CAN B+ line appears to be riding on another signal.

This vehicle was still under warranty by the Chrysler dealer. The dealership was backed up and could not look at the vehicle in a timely manner to have it ready for emissions testing. This is how our shop got involved. The vehicle was returned to the dealer at the customer’s request as the customer wanted the vehicle repaired under warranty, but after two weeks of reviewing this issue, the dealership threw in the towel. They stated they could not find anything wrong.

As a final note in terms of research, I ran a Carfax on this vehicle, which showed a new wiring harness and PCM were replaced on this vehicle before it was sold new in 2010. I find these facts interesting, but it still left our case unsolved.

This Pulling Codes case has not been resolved.