By Danjiela Haskin and Steve Mokdad of Bosch Automotive Service Solutions

Software in today’s vehicles has more than 100 million lines of code. Now compare that to the first shuttle launched into space, which only had roughly 50 million. And that’s just what’s on the market today. Automotive software will increase in complexity as digital transformations become business imperatives and vehicles transform into true smart entities.

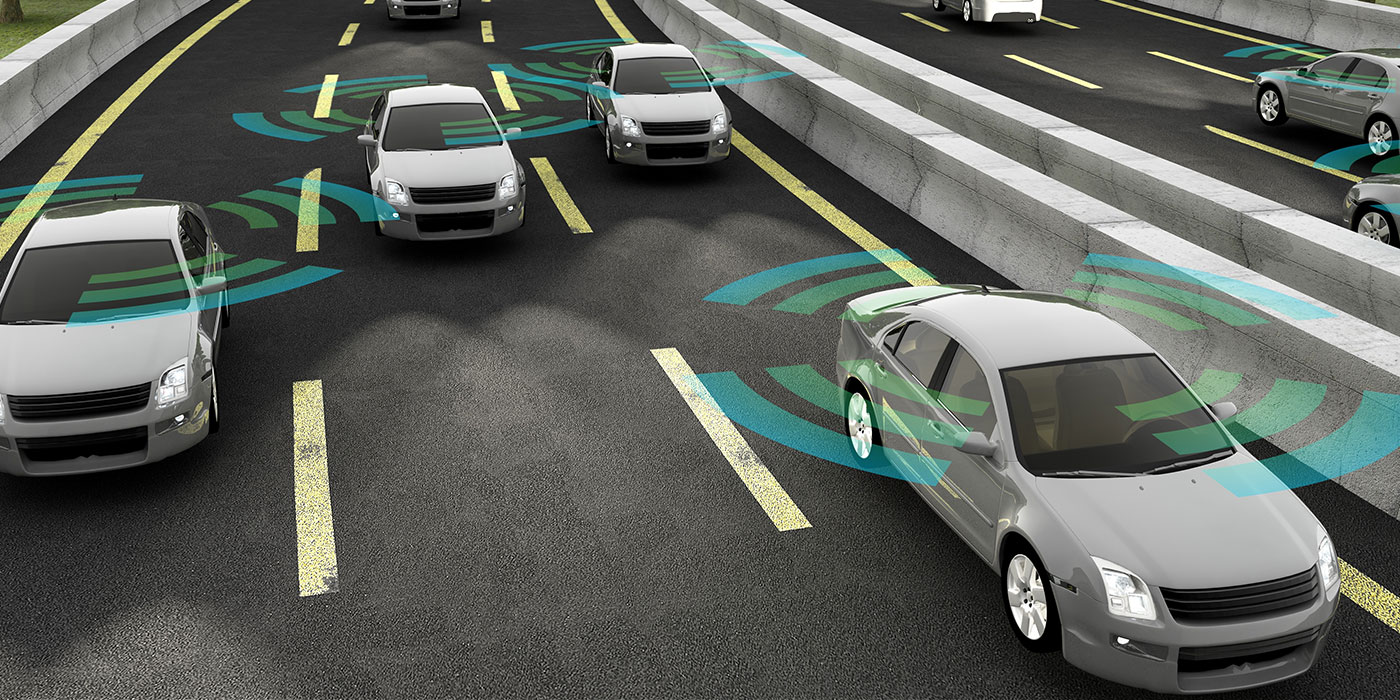

With trends in electrification and autonomous driving continuing, more and more decision-making will happen in our vehicles as we’re driving them. From detecting environments, vehicle-to-vehicle communications and understanding its position relative to pedestrians and buildings, all of this processing has to happen within the vehicle.

Opportunities for Workshops

How does this affect your vehicle repair shop? Essentially, you’ll want to start moving away from a focus on mechanical repairs and to a system software architecture type of diagnostics. This means investing in training, tools, and mechanisms to demystify what’s going on with a vehicle and make your life easier in the process.

From our experience, there are two key areas you can start to take advantage of now to prepare for the age of rapid digitization.

Increase of ADAS Features

According to AAA, most new vehicles have at least one advanced driver-assistance system (ADAS) feature. We’re just starting to tap into ADAS technology, and it’ll continue to become more pervasive as new cars are equipped with additional features.

If you’re repairing systems that factor into safety, it’s vital your ADAS equipment and calibration tools are accurate and complete. Even being off by a few degrees can mean the difference between life and death. So, you’ll want to know where the tests are coming from, the software’s origin, and ensure you’re getting the correct information from the original equipment manufacturers (OEMs).

While safety is the priority, efficiencies and ease of use are also important. A lot of these alignments can take 30 minutes to upwards of an hour, depending on the setup process. If you can cut that time in half or even to a fraction, you’ll be saving on labor, resources and costs.

Unique Demands for Electric Vehicles

As automakers like Ford, GM and others join the electric vehicle (EV) push, we’re headed toward an increasingly electric future. In fact, BloombergNEF predicts EVs will make up more than half of new passenger cars within the next 20 years.

Electric vehicle providers like Tesla often provide software updates over-the-air and franchised dealerships for repairs. However, as the industry grows, there won’t be enough dealers to keep up with demand, especially after warranties. By taking the initiative to prepare your shop today, you’ll be set up to seize these opportunities.

What does this mean? Since most fully electric vehicles have no internal combustion engine, special tests cater more to energy and thermal battery management. While the process will look similar — scans to figure out what’s wrong, determining trouble codes, etc. — it’ll be crucial for your scan tools to have the latest modules and software.

Considerations for Selecting Diagnostic Equipment

Diagnostic and recalibration tools are becoming more expensive and advanced, so you’ll want to make sure you’re investing wisely — nothing’s worse than spending money on equipment that quickly becomes out-of-date.

Here are some questions to keep in mind as you evaluate tools:

- What’s the platform longevity, and how stable is it? You don’t want the software to be outdated a year later and then have to buy something new.

- How often is the software updated? You’ll want access to the latest and greatest coverage as soon as it’s available and not have to wait for it.

- What coverage does it have? What types of vehicles can you diagnose using the product? Is it covering the breadth of models and manufacturers you need?

Lastly, you’ll want to have the ability to upgrade and move into other areas. Not all diagnostic systems are compatible with ADAS, for example, so even if you’re not getting into these calibrations now, having the ability to upgrade your current platforms down the road will be essential.

Your Shop of the Future Starts Today

Sensor technology is rapidly changing, and AI and 5G are starting to infiltrate the auto industry. It won’t be long before we have vehicles talking to cities, infrastructure and other vehicles. We can only begin to picture what that means from a diagnostic standpoint in the next two, five and 10 years.

For the technicians diagnosing these modern vehicles, the realm of knowledge now extends beyond the car to its surrounding environment. All of these different touchpoints will create much more of a challenge for the people in charge of repairs.

Ultimately, this shift makes it crucial for technicians to adapt and learn as vehicles become less mechanical and more complex. And for shop owners, plan on staying ahead of the curve and improving efficiencies to ensure you’re keeping up with the competition.

Danjiela Haskin is a diagnostics product manager at Bosch Automotive Service Solutions and Steve Mokdad, is a manager of product management at Bosch Automotive Service Solutions