In the everyday hustle and bustle of an automotive shop, no matter how careful and prepared you are, it’s easy for things to “slip” in the safety category. Every shop should have a safety program that outlines mandatory safety procedures and educates employees on best safety practices.

The program should cover all subjects and areas related to potential hazards and emergency preparedness including protective gear, first aid, fire safety and employer and employee responsibility.

Most of us are familiar with the Occupational Safety and Health Administration (OSHA). OSHA was formed to promote the safety and health of America’s working men and women by setting and enforcing standards. They are a great resource for information on safety for all industries.

One of the most common topics in a safety discussion is Personal Protective Equipment (PPE). PPE is equipment worn to minimize exposure to a wide variety of hazards. OSHA documentation states that “to ensure the greatest possible protection for employees in the workplace, the cooperative efforts of both employers and employees will help in establishing and maintaining a safe and healthful work environment.”

To further the explanation, OSHA has outlined the general employer and employee responsibilities:

Employer:

- Perform a hazard assessment of the workplace to identify and control physical and health hazards.

- Identify and provide appropriate PPE for employees.

- Train employees in the use and care of PPE.

- Maintain PPE, including replacing worn or damaged PPE.

- Periodically review, update and evaluate the effectiveness of the PPE program.

Employee:

- Properly wear PPE.

- Attend training sessions on PPE.

- Care for, clean and maintain PPE.

- Inform a supervisor of the need to repair or replace PPE.

In other words, it’s teamwork that will provide the most effective ongoing safety program in your shop.

Getting the Right Gear

OSHA requires that many types of PPE meet or are at least equivalent to standards developed by the American National Standards Institute (ANSI). Not only must employer-provided PPE meet these standards, but employee-provided and owned PPE must meet these standards as well. Eye and face protection, head protection and foot protection all must meet the ANSI standard.

Eye and Face Protection

To see or not to see, that is the question here, and I should think a simple answer for all of us. When you consider the safety program in your shop, consider the reasons that someone may not wear eye protection. Among the common excuses is that it slows someone down, it’s across the shop, it doesn’t fit right, it’s not comfortable, it doesn’t fit over my glasses and I can’t see well through them.

OSHA requires that eye and face protection be worn for any job when employees are exposed to the likelihood of hazards such as flying objects, liquid chemicals, acids, gases or light radiation. If their workers will be subjected to any of these situations, employers are required to provide the correct PPE and to ensure that it is worn.

To encourage that protective eyewear and face protection is worn, proper fitting and comfortable equipment should be available to all technicians and in a manner that makes it convenient for them to use. There is no excuse for an excuse, but they do happen even though wearing the proper protection is mandatory. Part of a shop safety program should be regular safety awareness meetings to make sure that no technicians have any excuse for not wearing eye and face protection.

Hearing Protection

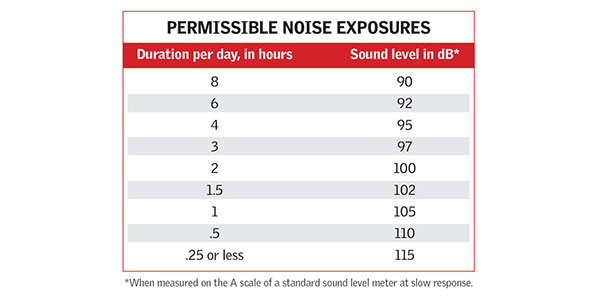

Determining the need for hearing protection involves a variety of factors including the actual loudness of the noise measured in decibels (dB), how long the exposure to the noise is going to be and the number of sources generating noise.

Automotive shops in general will certainly never be a quiet atmosphere, but the noise levels are not always a constant risk. The most common problem is the occasional tool or job that causes harmful noise exposure, such as running a vehicle without a proper exhaust system or using a tool that exceeds an acceptable noise level, such as an air hammer or bead seater.

Different people prefer different types of hearing protection, but disposable ear plugs are one of the most common and popular types. Earmuffs have the advantage that they can be put on and removed quickly, which makes them easier to use. Ease of use can encourage technicians to wear them, but they have a drawback in the fact that they require a tight seal around the ear to be effective and facial movements or glasses can keep them from working properly. Both types should be readily available around the shop.

Gloves

There are many different types of gloves, the difference being their intended use. Latex or nitrile gloves are two of the most common and will protect the skin against the majority of chemicals and oils being used in an automotive environment. Nitrile gloves tend to stand up better than standard latex, although both provide technicians with good dexterity.

Neither variety, however, provides long-term protection, and the two most common types of specialty gloves in an auto shop are chemical-resistant gloves for use in a solvent cleaning tank and welding gloves. These should be inspected regularly for condition and replaced if worn or damaged.

Mechanics gloves, as they are commonly known, are a popular choice among technicians for protection. They fit well with only a small loss in dexterity, but an important feature of these gloves is the level of padding they offer, which is important to protect against the negative effects of vibration and impact transferring into the hands and wrists.

Safety Teamwork

Near the beginning of this article, I quoted OSHA documentation, which stated, “the cooperative efforts of both employers and employees will help in establishing and maintaining a safe and healthful work environment.”

This statement is an excellent basis for a shop safety program. All employees should take part in promoting a safe working environment, and the promotion and implementation of this idea will also help to improve morale and employee relations.

It is the responsibility of the employer to provide the PPE, and while it is required of the technicians to wear it, it is also the technicians who hold the responsibility to do so and to “police” the issue in the shop.

Friendly reminders between technicians to wear PPE is one of the best ways to ensure that it is being worn. This type of teamwork develops from having a structured safety program and overall good shop morale.

All technicians should provide an audible warning when preparing to use any tool or equipment or perform any procedure that will be excessively loud, with ample time given for coworkers to don their hearing protection.

Fire Safety

As fire is one of the most frightening possibilities in any shop, fire safety should never be overlooked. Regular inspection of fire extinguishing equipment is mandatory, but routine safety reviews, as well as employee training, should be a key to your safety program.

Even if it is assumed that everyone knows how to properly extinguish a fire and is comfortable with it, this is not always the case. This is a critical area because the difference between a fire being extinguished or being out of control is defined by a matter of seconds.

As part of your shop’s safety program, a good practice would be to check with your local fire department for regulations to see if they offer any training or demonstrations to provide employees a greater understanding and experience of what to do in case of a fire.

In a business where you deal with many flammable liquids and many sources of ignition, fires can happen and there is a good likelihood that a fire will happen. It’s best to be prepared.

First Aid

A properly equipped first aid kit and equipment is an OSHA requirement, and first aid supplies usually require regular attention. No matter how careful we are, we’re in an industry where small cuts and abrasions are common, so expect that supplies will be used.

It’s a good practice to have base level first aid training, and while it is always the goal to avoid all injuries, the reality is that a serious one may occur at some point.

Even with basic training, some people are more comfortable with medical emergencies than others, and it’s beneficial to have someone who is considered a lead, should a situation occur. Be it a serious injury or a something such as choking, it is not uncommon for panic to set in, both with a victim as well as others who are not used to emergency situations.

As first aid awareness becomes more commonplace, training, supplies and equipment have also become readily available for a greater number of medial emergencies such as the Heimlich maneuver for choking, Cardiopulmonary Resuscitation (CPR) and the use of an Automatic External Difibulator (AED) for situations involving a heart attack or stopped breathing.

BE PREPARED

Safety should be serious business in your shop. A safety meeting with employees may bring light to deficiencies in your shop safety program. Whether you find that you are well equipped for everyday safety practices and emergency procedures, or whether you need additional training and investment in equipment, there’s no substitute for being prepared.