ISN Expands Freedom Program for Mobile Tool Dealers

ISN’s Freedom Program is designed to provide experienced, successful mobile tool dealers with support to become an independent mobile dealer and expand their growth.

Integrated Supply Network (ISN) said it has expanded its Freedom Program for mobile tool dealers.

ISN’s Freedom Program is designed to provide experienced, successful mobile tool dealers with support to become an independent mobile dealer and expand their growth. The program provides businesses with all the sales, marketing, purchasing and financial support needed to excel as an independent mobile tool dealer, according to ISN.

TechShop, ShopOwner Offer $50 For Good Guesses

Guess the Tool for a chance at cold hard cash!

TS Toolbox Guide February 2024

Here’s a look at some of the core feature and modern frills to consider when it’s time to move into a new office.

Embracing Cutting-Edge Solutions the Industry has to Offer

Embracing cutting-edge solutions is strategic and imperative for technicians navigating the constantly changing landscape of automotive maintenance and repair.

TPMS: Are Retrofits in Your Future?

Installing a retrofit kit can be performed with the tools and equipment you already own and use on a daily basis.

Other Posts

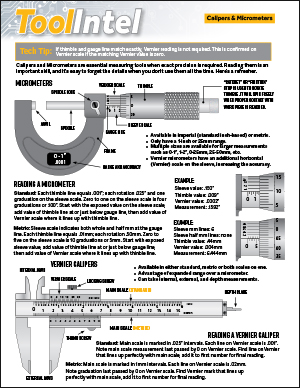

#2 Calipers & Micrometers

Calipers and Micrometers are essential measuring tools when exact precision is required.

Snap-on Continues to Offer Free Weekly Product Training Sessions

The online training and question and answer sessions are free of charge.

Repairify Announces Executive Leadership Changes

The company has named Craig Edmonds as president of asTech among other executive appointments.

PRT Launches 22 New Products on Complete Strut Assemblies

The new items come to expand the PRT portfolio in North American Market and represents more than 12 Million vehicles in new coverage.