TOPDON USA Makes $25,000 Donation to TechForce Foundation

To date, TOPDON has donated over $66,000 to aid organizations and schools that are dedicated to preparing the next generation of auto technicians around the world.

TOPDON USA, the nation’s premier provider of cutting-edge technology and advanced tools for auto repair professionals and enthusiasts, announced today the donation of $10,000 cash and $15,000 in products to TechForce Foundation, a nonprofit organization dedicated to supporting the education, training and career development of aspiring auto technicians. To date, TOPDON has donated over $66,000 to aid organizations and schools that are dedicated to preparing the next generation of auto technicians around the world.

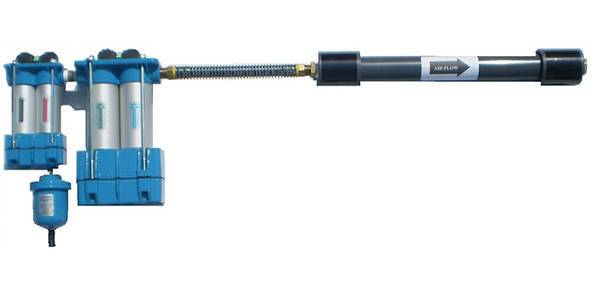

AMD-035 Membrane Dryer Provides Ultra-Clean & Ultra Dry Air

The dryer has a flow rating of 35 SCFM and maximum working pressures of 150 PSI.

BendPak Full-Rise Scissor Lift Delivers Two-Post Performance

SP-7XE scissor lift lays flat and raises a vehicle six feet with an open center below.

BendPak to Debut Eight-Armed Car Lift Concept at NADA

Octa-Flex improves technician productivity, convenience and ergonomics, according to BendPak.

Matco’s New Ghost Cart: Where Tools and Style Spookily Align

Haunt your shop with efficiency: Matco’s 2023 Ghost Cart is sleek and functional.

Other Posts

Registration Open for ETI ToolTech 2024

The event will be held on April 22-24, 2024 in Newport Beach, CA, at the VEA Newport Beach Marriott.

TEXA Releases IDC5 CAR 76.5.0 Update

IDC5 CAR 76.5.0 is characterized by over 2600 new possible selections for the major makes on the market worldwide.

ISN Expands Freedom Program for Mobile Tool Dealers

ISN’s Freedom Program is designed to provide experienced, successful mobile tool dealers with support to become an independent mobile dealer and expand their growth.

Snap-on Continues to Offer Free Weekly Product Training Sessions

The online training and question and answer sessions are free of charge.