All vehicles with variable valve timing (VVT).

Condition

After a VVT actuator, chain/belt or guides have been replaced, codes P0010-P0025 and manufacturer codes for camshaft and crankshaft synchronization or correlation are set in the ECM. The engine may have diminished performance.

Cause

The timing of the engine might off. The most likely reason for the misalignment is that the relationship between the VVT actuator, sprocket and camshaft has been altered during the installation of new components.

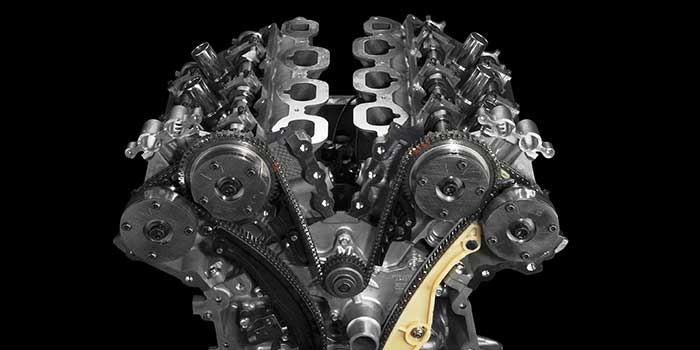

Most VVT systems you are likely to encounter will be those with hydraulically changed camshaft actuators, although a few (such as Lexus VVT systems) use an electric actuator to advance or retard cam timing. The camshaft actuator changes camshaft and valve timing by rotating the relative position of the camshaft slightly fore or aft compared to its normal base timing setting.

The weak point of the system is typically the camshaft actuators. This component is expensive to replace, costing anywhere from $100 to nearly $300 each depending on the application. If the guides and chains are also replaced as part of the job, the total job can cost between $1,000 and $2,000 depending on the engine.

The weak point of the system is typically the camshaft actuators. This component is expensive to replace, costing anywhere from $100 to nearly $300 each depending on the application. If the guides and chains are also replaced as part of the job, the total job can cost between $1,000 and $2,000 depending on the engine.

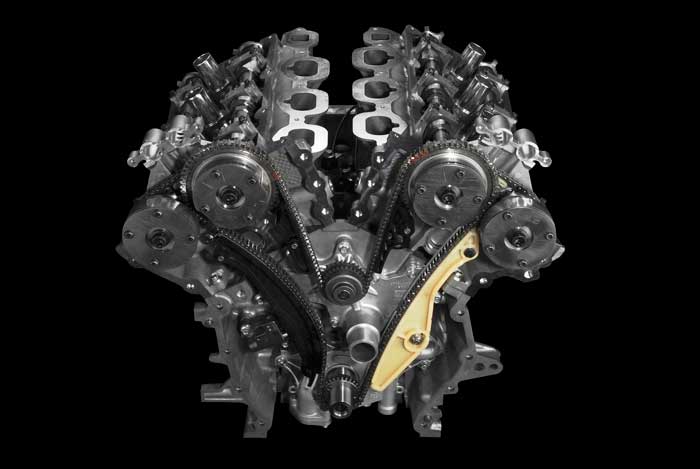

In some cases, the original camshaft actuator has a locking mechanism that keeps the camshaft in place until there is enough oil pressure. This may allow the camshaft to rotate uncontrolled up to 30-50 degrees in some cases. During startup, the valvetrain might make a knocking or clicking noise.

When the new actuator or chain/belt is installed, the timing is off even if the chain was not removed. Also, the camshaft can be turned due to the pressure of the valve springs due to the position on the camshaft’s lobes.

Solution

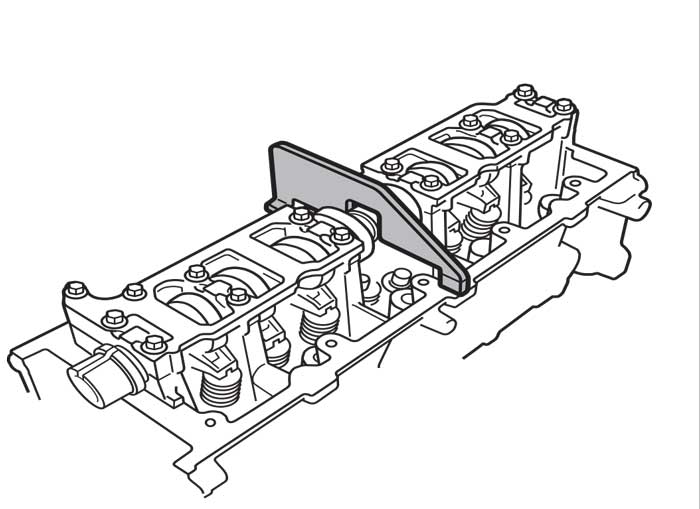

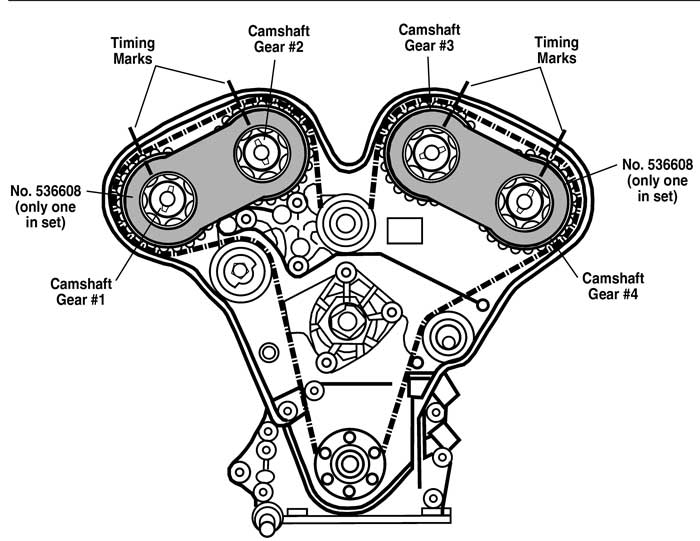

Even if the technician uses a paint marker to line up the chain/belt and sprockets, there is still a possibility that the timing can change due to actuator and camshaft movement on some engines. The solution is to lock the camshafts, actuator and, in some cases, the crankshaft. Tools are available to lock the position of the crankshaft, camshafts and actuators. These tools can prevent movement as new components are installed.

The other key is to follow the service procedure in the service information. The list of tools required to lock down the crankshaft and camshafts is often included in the procedures. Trying to engineer your own tools could cause a comeback and possible damage to the customer’s vehicle.

Variable valve timing has been standard on most vehicles for the past decade and is even on pushrod motors like GM’s LS engine after 2008. Investment in tools to service timing chains and belts will pay off in the form of increased productivity, but as an insurance policy against comebacks.