Models Affected: 2005-’06 Legacy, Outback, Impreza and Forester vehicles equipped with 4EAT

The purpose of this bulletin is to assist when diagnosing DTCs P0851 (Neutral Switch Input Circuit Low) and P0852 Neutral Switch Input Circuit High). If you encounter a vehicle with DTC P0851 and/or DTC P0852, use the following repair procedure.

Repair Procedure/Information

Using the Subaru Select Monitor, check for diagnostic trouble codes stored in memory. If DTC P0851 and/or DTC P0852 are stored in memory, adjust the inhibitor switch and select cable.

Note: Refer to the applicable Subaru service manual found on the STIS website for component removal to gain access to the inhibitor switch and select cable. It’s critical that the following adjustments are performed correctly.

Adjustment for inhibitor switch:

1. Set the select lever to “N” range.

2. Loosen the three inhibitor switch securing bolts.

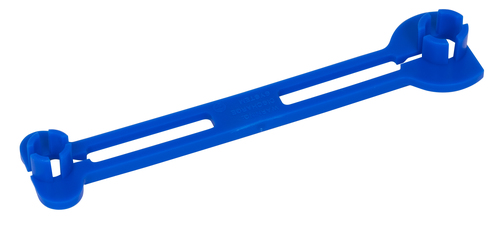

3. Insert ST (special tool) 499267300 Stopper Pin as vertically as possible into the holes in the inhibitor switch lever and switch body. See Figure 1.

4. Tighten the three inhibitor switch securing bolts, and then remove the special tool.

Tightening torque: 3.4 Nm (2.5 ft.-lb.)

Adjustment for select cable:

1. With the select lever already in the “N” range, loosen adjusting nuts A and B on both sides. See Figure 2.

2. Turn adjusting nut B until it lightly touches the connector. See Figure 3.

3. Use a spanner wrench to hold nut B so that it does not rotate, and then tighten adjusting nut A. See Figure 4.

Tightening torque: 7.5 Nm (5.5 ft.-lb.)

4. After the completion of the adjustment, confirm that the select lever operates normally at all ranges:

– Move the select lever from “P” to “D” range. Check that the detents could be felt in each range. If the detents cannot be felt or the position pointer (dash indicator) is improperly aligned, re-adjust the cable.

– Check if the starter motor rotates when the select lever is set to “P” range.

– Check the back-up light illumination when the select lever is in “R” range.

– Check the parking lock operation when the select lever is in “F” range.

5. Clear the DTCs stored in memory.

If the codes return after the correct adjustments, refer to the diagnostic procedure found in the applicable Subaru service manual.

Courtesy of Mitchell 1.