Several aftermarket companies offer laser alignment tools for accessory drive systems that can be very helpful in eliminating drive belt noise in the models below as a result of misaligned pulleys.

Models:

2009 and Prior Saab 9-7X

2010 and Prior GM passenger cars and trucks (including Saturn), and HUMMER H2 and H3 vehicles

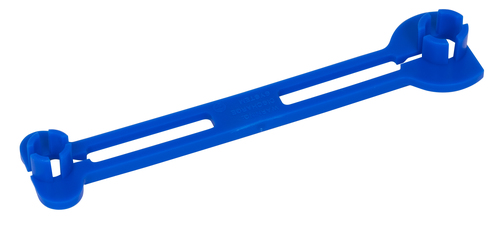

The EN-49228 Laser Belt Alignment tool was designed to help in eliminating drive belt noise as a result of misaligned pulleys. This precise, simple-to-use and time-saving tool is used to assist technicians in achieving accurate alignment of drive belt pulleys.

This special service tool removes the guesswork from achieving proper alignment of the pulley and may reduce comebacks from drive belt noise, accelerated drive belt wear or drive belt slippage.

Caution:

– Do not look directly into the beam projected from the laser.

– Use caution when shining the laser on highly polished or reflective surfaces.

– Laser safety glasses help reduce laser beam glare in many circumstances.

– Always use laser safety glasses when using the laser. Laser safety glasses are not designed to protect eyes from direct laser exposure.

1. Observe and mark the serpentine belt orientation. See Figure 1.

2. Remove the serpentine belt from the accessory drive system.

3. Install the tool onto the power steering pulley. Position the legs of the tool into the outer grooves of the pulley, farthest from the front of the engine. See Figure 2.

3. Install the tool onto the power steering pulley. Position the legs of the tool into the outer grooves of the pulley, farthest from the front of the engine. See Figure 2.

4. Install the retaining cord around the pulley and to the legs of the tool.

5. Put on the laser safety glasses provided with the tool.

6. Depress the switch on the rear of the tool to activate the light beam.

7. Rotate the power steering pulley as required to project the light beam onto the crankshaft balancer pulley grooves.

8. Inspect for proper power steering pulley alignment.

– If the laser beam projects onto the second rib or raised area (Figure 3, arrow 1), the pulleys are aligned properly.

– If the laser beam projects more than one-quarter rib 0.9 mm (0.035”) misalignment, adjust the position of the power steering pulley as required.

– Refer to SI for Power Steering Pulley Removal and Installation procedures.

9. Install the serpentine belt to the accessory drive system in the original orientation.

10. Operate the vehicle and verify that the belt noise concern is no longer present.

Courtesy of ALLDATA.