In the same manner that a hammer is designed to drive nails and a wrench is engineered to turn fasteners, a screwdriver is designed to tighten or loosen screws. A great deal of effort goes into designing, testing and manufacturing the best tools for these applications, yet flat tip screwdrivers are sometimes used for applications that they are not suited for such as prying, striking and scraping. Using a screwdriver blade incorrectly can result in damage to the screwdriver, the work material and, most importantly, may seriously injure the user or bystanders.

Technicians work hard and their time is precious. Injuries often occur when a tool is used improperly in haste, when one is busy and grabs the nearest tool instead of the best tool for a specific job. So what are the differences between flat tip screwdrivers and pry bars and why are these attributes important?

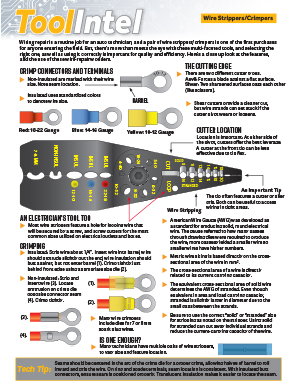

Material & Hardness: Screwdrivers typically exhibit a higher Rockwell hardness when compared to pry bars. This hardness corresponds to higher strength for turning force characteristics and better wear for long term life of the product. A pry bar has a lower Rockwell hardness, which is more suitable for bending as is seen in prying applications. Snap-on screwdrivers are manufactured from special alloy tool steel that has superior strength and toughness for optimum performance.

Shank Thickness: Screwdriver shanks are generally thinner than similar length pry bars. For example, a Snap-on MPBS12 Straight Tip Pry Bar uses a 3/8” square shank while a Snap-on SDD48 Flat Tip Square Shank Screwdriver uses a 5/16” square shank, making the screwdriver less suitable for prying. Snap-on screwdrivers have a unique cold formed bolster, found on Snap-on round shank screwdrivers, allowing the user to apply additional torque to the shank for really tough applications.

Insertion Distance: Pry bars are of the best quality when they are designed so that the pry bar is fully inserted into the handle and contacts the striking cap within the handle. Screwdriver blades, as well as some poor quality pry bars, typically are not inserted as far into the handle which makes them not well-suited for leverage applications.

Striking Design: Screwdrivers are not designed to be used as striking tools. Impact with a hammer can cause the handle to split, mushroom, fracture tips or allow the blade stem to penetrate the handle. Pry bars that incorporate a full contact striking cap will transmit the maximum force to the pry bar tip and eliminate the problems noted with screwdrivers.

Tip Geometry: Screwdriver tips and pry bar tips differ dramatically, making them the most suitable for their intended tasks. For example, the flat tip on a Snap-on MPBS12 pry bar is approximately 3/32” while a SGD6BR screwdriver tip is only 1/16” thick. Moving up from the tip one inch, the thickness difference is 9/32” versus 3/16”, respectively. By placing more steel mass closer to the contact area, a pry bar offers better load capacity versus a screwdriver tip.

The bottom line is that it is important to choose the right tool for the job in order to get the job done correctly, on-time and, most importantly, safely. Do not use screwdrivers for any prying, striking or scraping applications.

Courtesy of Snap-on Tools.

For information of products offered by Snap-on, visit www.snapon.com.