In the red corner, weighing in at 4.5 pounds and boasting 1,300 career foot-pounds of torque is the one and only, the tried and true, the master bolt blaster…pneuuuuu-matic Twin Hammer!

And,in the blue corner, tipping the scales at just over 6 pounds, with 1400 career foot-pounds of torque is the up-and-coming challenger, the nimble, the quick hitting, the brushless behemoth…Coooordless Crusher!

What’s your prediction on today’s fight? Twin Hammer has the experience and just never runs out of steam, but Cordless Crusher is hitting harder every year, with energy in reserve longer than most fights will go. Will there be a decisive victory? What’s going to be in your toolbox?

As an auto technician, it’s a tough call. The tools you choose depends on the specific job at hand, and in the case of pneumatic vs. cordless, the decision likely isn’t going to be one or the other, it’s going be both.

Pneumatic tools have traditionally always been the tried-and-true auto technicians’ choice, to the point where the sound of an air tool is the most recognizable and defining characteristic of an auto shop over any other. Air tools have always been the “staple” power tools because anywhere there’s an auto repair shop, there will be compressed air, so there’s always a power source for an air tool.

You never have to plug them in or charge them, you don’t have to replace the batteries, worry about them going dead right in the middle of something, or worry about them being superseded by a higher voltage model that requires a different battery. Compressed air is compressed air, and it always will be.

I don’t imagine this advantage of air tools will ever change as compressed air is too valuable for too many reasons. Air tool popularity can also be related to their fundamental mechanical nature. There’s something about a tool that can sit for years and years, and still work perfectly when you dust it off. Of course, our tools don’t sit around, but you get the idea.

Air tools also have the weight advantage with lack of a heavy battery, and modern materials have not only made them lighter and more durable over the years, but they’ve gotten smaller in size allowing better access into tight areas. Improved ergonomics and balance have been fundamental design considerations for years, and along with better sound control and increased power, air tools will always have a place in an auto shop.

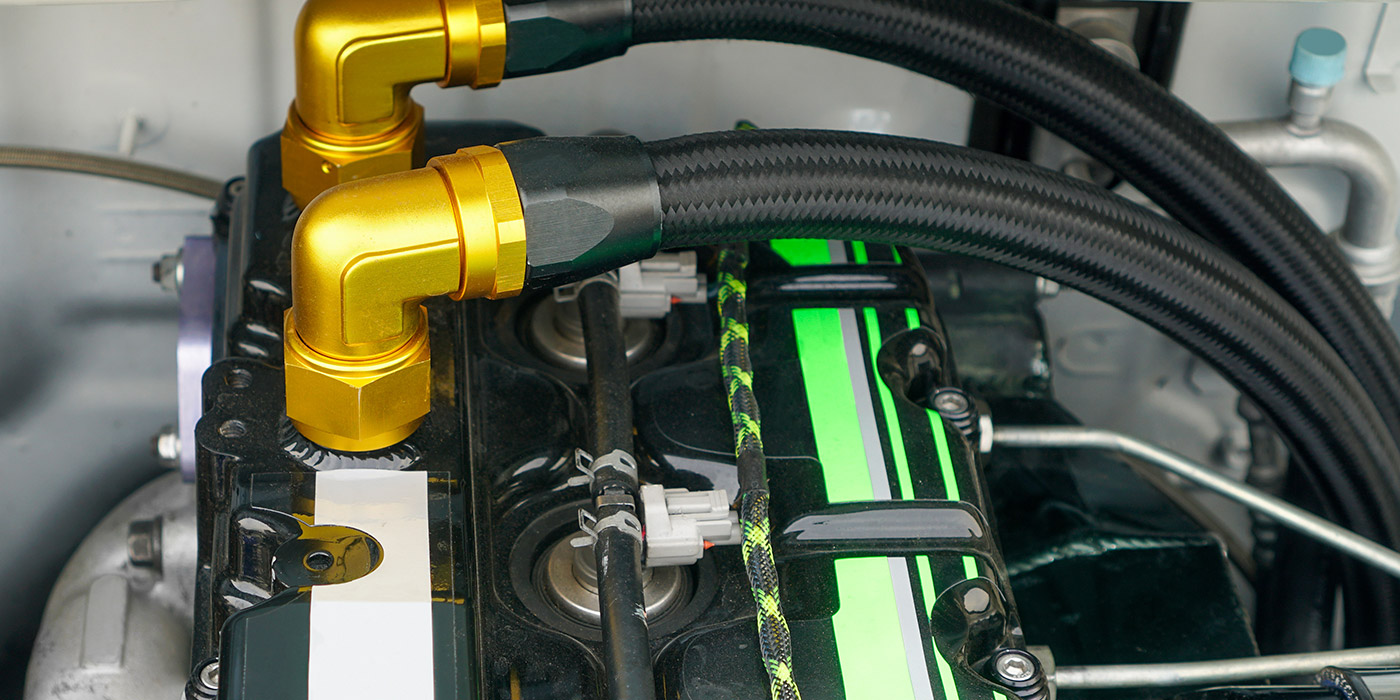

So, air tools came out swinging, but cordless can throw a few punches of its own with some of the drawbacks to air power. One is the air delivery system in shops, i.e., the hoses and lines. More often than not, system pressure is fine, but the dynamic pressure, or the pressure available when the tool is in use, is considerably less than it needs to be for proper air tool performance. The problem is usually caused by restrictions in the lines or hoses, but cordless doesn’t care.

Citing poor air tool performance due to the shop air system – that’s hitting below the belt. But air tools come back with a few jabs of their own, with some manufacturers designing built-in gauges on air tools to indicate if the proper dynamic pressure is available.

Now cordless has a sucker-punch. What’s that hose? It’s always there and you can go only so far, not to mention tripping over it, having to clean it and hanging it up. And, what about one of those days when there’s a lot of air being used, and you need to wait for the compressor to catch up? And, air tools need to be oiled before and after use to keep them in good condition, and some require greasing. That’s a lot of maintenance.

Then air comes back with a quick one, two. Batteries are expensive, which is why we usually only have two. If it has a battery, it will need recharged at some point, Pneumatic, on the other hand, keeps going and going (couldn’t resist) with the power source that’s always there. In cases where you’re doing constant sanding or drilling, pneumatic is often the only way to go.

Air tools have traditionally had the power advantage that no electric tool could touch, but cordless is sitting back, waiting to deliver a left hook.

Everyone knows how good batteries have gotten thanks to Lithium-ion (Li-ion) technology. Although cordless tools lose the weight battle, primarily because of the battery, higher voltage and advanced battery technology is providing the power and shaving off weight at the same time.

Two performance factors that can be attributed directly to a Li-ion battery are run time and output consistency. There was a time when you always needed a battery on the charger, and diminishing output was an expected performance aspect of a cordless tool. Now, you may get a day’s use out of a charge, and power output remains consistent with no drop off, down to the last ounce of energy.

The increasing use of brushless motors has added another level of performance to a cordless tool. In the automotive business, we’re all familiar with brushed motors, and we know the brushes wear as the armature and commutator rotate. In a brushless motor, the armature is fixed and surrounds the magnets, which rotate with the motor shaft. This eliminates the brushes, commutator and the related friction between the two, and the current in the armature is electronically controlled.

The armature windings can also be larger since they are on the outside, and the motors can therefore be more powerful. It’s the little things such as this that add up to keep cordless tools in the fight with the power of pneumatic. Maintenance is also less, and when time is money, that’s an important factor.

So, the big question, who will take the title? This is a fight that will go the distance.

I’m not willing to give up my air tools or my cordless tools. What does the future hold? Will one gain the upper hand over time? It’s hard to say, but for now, I’d say it’s a pretty fair fight. TS