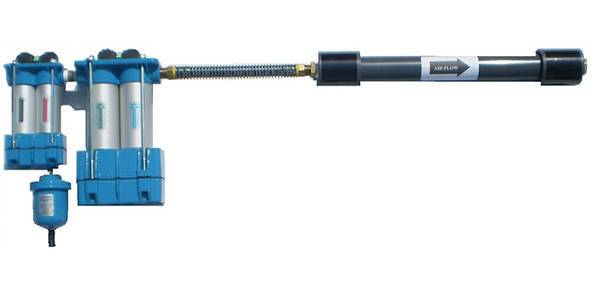

Hunter’s new OCL430HD rotor lathe greatly improves medium- and heavy-duty service by machining the rotor on the vehicle. Hub-mounted service eliminates the need to disassemble the hub to remove the rotor, saving a tremendous amount of time and effort. Machining the rotor on the hub also significantly reduces runout, providing a more precise cut and extending the life of expensive rotors.

Hunter’s new OCL430HD rotor lathe greatly improves medium- and heavy-duty service by machining the rotor on the vehicle. Hub-mounted service eliminates the need to disassemble the hub to remove the rotor, saving a tremendous amount of time and effort. Machining the rotor on the hub also significantly reduces runout, providing a more precise cut and extending the life of expensive rotors.

The OCL430HD includes all of the operational features of Hunter’s popular OCL410 light-vehicle brake lathe, yet adds more robust lathe components to handle larger rotors.

With a reinforced cutting arm and rugged tool holders, the OCL430HD resurfaces rotors up to 17.5 inches in diameter and up to 3.5 inches in thickness. A 1.5-hp, 230 VAC motor provides the additional torque required for medium- and heavy-duty trucks.

The patented ServoDrive system enables technicians to vary the spindle speed and rotational torque of the lathe while in operation. This unique ability allows the technician to adjust the speed “on the fly” without compromising the final surface finish. ServoDrive also provides the capabilities needed to activate other patented features including computerized compensation and anti-chatter safeguards.

Pro-Comp computerized compensation adjusts for lateral runout with a push of a button and a simple single-point adjustment, allowing the technician to quickly complete the machining of the rotor within OEM specifications.

ACT (Anti-Chatter Technology) minimizes machining problems by virtually eliminating chatter. ACT oscillates the speed of the lathe while machining the rotor to prevent the buildup of vibration that can occur on any fixed-speed lathe, requiring extra time to install chatter-dampening accessories.

The OCL430HD trolley provides an extended low-to-high working range required for serving vehicles when a lift rack is not available or practical.

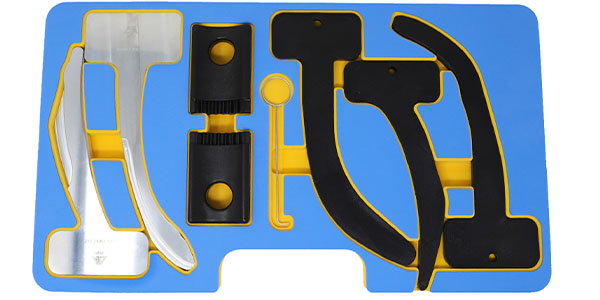

A full selection of adaptors and accessories to match OE specifications of medium- and heavy-duty commercial-grade vehicle hubs and rotors is also available from Hunter.

Hunter Engineering is the leader in alignment systems, wheel and tire service, brake service and inspection lane equipment. Hunter equipment is approved and used by vehicle manufacturers, automobile and truck dealers, tire dealers and service facilities around the world.

For additional information about Hunter, visit our website at www.hunter.com or contact Robert Bruce, advertising manager, Hunter Engineering Company, (314) 716-0443.