Courtesy of ShopOwner, by Vic Tarasik

At the end of last year, I had the opportunity to spend a week with several industry professionals, including Bill Nalu (Interstate Auto Care) David and Jeannie Light (Lighthouse Automotive), Clint White (CWI Coaching with Integrity), and many others. We were all brought together to discuss and pose solutions to some of our industry’s most pressing matters.

At the opening session, well-known industy commentator Carm Capriotto introduced several discussion topics. One that took hold and became a central point of the conversations over the days was industry image. Specifically, the image of the technician, and how we as an entire industry refer to them. Many people incorrectly refer to techs as “installers;” some call them “mechanics;” and most of us use the term “technician.”

Carm referenced the Hulu series, “The Bear.” The show is about a Michelin-starred chef who returns home to run his family’s sandwich shop. What he finds is a series of dysfunctions, one of which is how the team refers to one another. The beginning of the transformation of the kitchen staff begins with one simple term: “Chef.”

If you have spent any time in the kitchen of a restaurant, you’ll hear that common term used in many different ways. From the Head Chef to Sous Chef to the Pastry Chef, the “technicians” in the kitchen are each referred to as Chef. Even if their skills are not matched to the position yet, they are still the Chef of that position.

In one of my recent columns for ShopOwner magazine, I discussed looking at various levels such as A, B, C technicians and broadening the tiers to increase the levels of each position. I still believe we need levels to manage the growth in skills and compensation as each technician grows in knowledge and abilities.

I also believe the concept of what we call each other can be transformative to our industry and I suggest we consider a new term: “Specialist.” As our group of influencers worked through the topic, many thoughts came to my mind on how we as an industry have taken each next step in our evolution from grease monkey to mechanic to technician.

Now, it’s time to move on from technician and seriously consider adopting the term “specialist” as our new moniker.

As an ASE Master Technician with decades of experience, I fully relate to the complexity, knowledge and skills required to service vehicles, whether they be from yesteryear, the 1980s or to today’s highly advanced vehicles. The term technician simply doesn’t do the skills required any real justice.

There are, of course, things to consider.

Changing perceptions is like moving an ocean liner

Just as today’s largest cruise ships or super-tankers are slow to turn, changing the perception of those outside the shop’s four walls will take time. It will also take effort and your internal drive to make it happen.

Change starts and is sustained at home in your bays! No person in your shop achieved the level of skills needed to serve the customer with five-star service or flawless repairs overnight. Time and dedication were and are still required to grow and maintain. The one and done approach doesn’t work in the shop and it won’t work here.

All the horses jump and no chipped paint.

When Walt Disney envisioned Disneyland, he set out for it to be significantly different than amusement parks he’d visited as a young man. At that time his favorite ride was the carousel, but rides at the typical carnival were not always well-maintained. Chipped and faded paint were the norm and rides often broke down.

Once, when Walt attended a carnival and it was his turn to get on the carousel, he mounted a horse that was broken. The horse didn’t “jump” like the rest.

Years later, Walt Disney set out to do what others hadn’t done; build a place where, in his words, “All horses jump and there’s no chipped paint”. Excellence is intentional!

Does your team and do your bays exude professionalism? Simple things like a rag in the back pocket, excessively loaded tool cart or a cluttered service desk will send a message, one that isn’t conducive to professionalism.

GP or Specialist?

Over the past 12 months, I’ve had the “pleasure” of undergoing 4 surgeries; two hip replacements and two carpal tunnel surgeries. In each case, I was referred to the specialist in that field and, in each case, all four of the surgeries gave results far beyond what I had anticipated.

Had my general practitioner performed them, I am sure the results would have been different!

Consider the general practitioner as the GS in your shop and the surgical specialist as the alignment, diagnostic or mechanical specialist at your shop.

Making room for it

During our conversations about terminology, several industry participants pushed back on the term specialist, simply because it wasn’t earned. But, as in a commercial kitchen, the role is always termed Chef, not because of their skills but because they occupy the position. It’s a lot like the President of the United States. No matter how presidential they act or perform, they are still the President because they occupy the office.

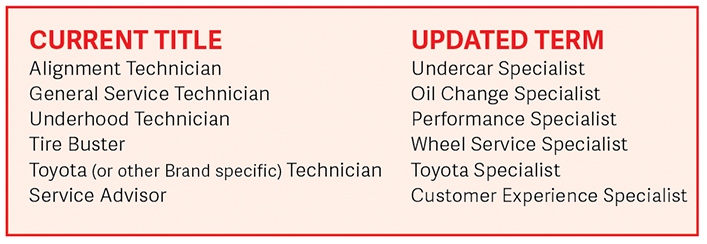

Make room for the person in that position. A diagnostic specialist in your shop has the base skills to grow into the role because of their abilities. In order to maintain the position, they will have to commit to ongoing education to stay up to date with new technologies and skills required for that position. The same goes for each area in your shop. Let’s look at a few of the common positions in a shop and how you could refer to them instead.

Over the years we have been called many things. Sometimes friendly to our face; some, when out of our earshot, are not so nice. No matter what we have been called – grease monkey, mechanics, technician – they all pale, some more than others, to specialist.

Pick your poison. Do you want to stay the same or will you make the effort to provide jumping horses and chip-free paint? Excellence begins with the words you use!