In preparation for the 2013 Daytona 500, NASCAR unveiled a new track drying system called the Air Titan. The Air Titan featured Sullair 1600HAF portable air compressors and, in the event of a rain delay, was designed to dramatically reduce track drying time when compared to jet dryers used in previous years.

In preparation for the 2013 Daytona 500, NASCAR unveiled a new track drying system called the Air Titan. The Air Titan featured Sullair 1600HAF portable air compressors and, in the event of a rain delay, was designed to dramatically reduce track drying time when compared to jet dryers used in previous years.

Following the challenges of rain delays at the 2012 Daytona 500, NASCAR Chairman and CEO Brian France challenged the NASCAR Research and Development Team to deliver a new track drying system that would ultimately reduce the drying time by as much as 80% — from 2-1/2 hours to around 30 minutes. To accomplish this NASCAR pursued alternative technologies to the jet drying system. NASCAR’s R&D Group was up for the challenge and contacted Ring Power Corporation, a Sullair distributor and a Caterpillar dealer located in St. Augustine, Fla. to pursue the possibilities of using compressed air. In just six months, starting in August 2012 with the February 2013 Daytona 500 date in sight, the NASCAR Team and Ring Power worked together on a solution that not only reduced drying time to around 30 minutes, but was much more energy efficient. Jerry Kaproth, Special Projects Coordinator for NASCAR was very pleased with the results from the NASCAR R&D team and the professional support he received from both Ring Power and Sullair. Kaproth emphasized the advantage of the new Air Titan is twofold, “one, it dries at a much faster rate than the jet dryers, and two, it’s a lot more energy efficient than utilizing the jet dryers.” Regarding the difference in fuel consumption, he went on to state “we figured that the ratio of the compressors compared to the jet dryers is about 9 to 1 in our favor now.”

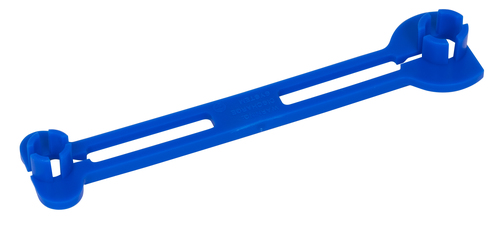

The system includes three side-by-side Air Titans, each enclosed in a six-foot cart and towed behind a truck. The Air Titans are connected by a three-inch air hose to three Sullair 1600HAF high pressure air compressors positioned on a flatbed truck that follows alongside the truck that is towing the Air Titans. Each Air Titan has a long, thin air nozzle that delivers high pressure air to the wet racetrack, forcing the water down to the apron where it is vacuumed up by another truck.

When asked about working with Ring Power and Sullair on the Air Titan project Kaproth stated, “both organizations were extremely professional. Ring Power has been reliable, innovative, and responsive, as they met every challenge. Sullair provided a wonderful piece of equipment and provided professional support to us as well.” Kaproth believes that, “this system, in some form or fashion, could be utilized at every Cup event for NASCAR. But along with the Cup events, we also have an opportunity to look at other racing series.” Whether the Air Titan is needed to dry the race track or not, the equipment is always there, ready to meet the challenge.