The corporate world has offices. You hang pictures on the wall, keep a few trinkets on your desk and a few snacks in one of your desk drawers. It’s your space. As technicians, we have our toolbox. It’s our “office” on wheels. But it’s different. We have no “work from home” option. We can’t take it with us and work at a coffee shop. Our “office space” becomes far more important. This is where we make our living.

The size of a toolbox and the features we choose depend on multiple factors, which have changed over the years along with automotive and tool technology. Here’s a look at some of the core features and modern frills to consider when it’s time to move into a new office.

Real Estate

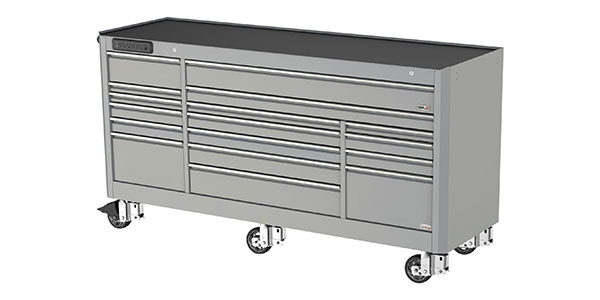

If you said “toolbox” forty years ago, the picture in a technician’s mind was a typical single-bay, top and bottom box. There was a time when these would last a lifetime in the industry. But let’s face it, today, we need a lot more space. There are far more special tools and an almost endless list of diagnostic equipment that a technician needs to work on today’s cars, and it doesn’t take long to run out of space in a toolbox.

A double-bay configuration is almost always considered the minimum, and for the most part, it can take quite a few years to fill one up, but what happens when you do? The options are to build up or build out. In real estate, they always say a two-story is cheaper than a ranch. That might be true with houses, but not with toolboxes. It’s expensive no matter which way you go.

However, it’s important to consider the benefits of going one way or another. A triple-bay box adds a row of drawers and the advantage of both a triple- or double-bay is the work area on top. It’s nice to have a space large enough to set tools or a laptop computer, and still have room to work on small components or lay out parts.

The drawback to a triple-bay or larger is the footprint. Some shops have limited space. Usually there’s enough for a double-bay, but anything wider can sometimes pose a problem. This is where the real-estate rule comes into play. There’s always room to build up. This can be a huge advantage where space is a concern, but the drawback is you lose the work area on top. Some of the higher drawers aren’t as convenient for frequently used tools, but ideal for specialty or tools you don’t use often.

Casters

Casters don’t often get the attention they deserve. They’re sometimes forgotten. Admittedly I’ve yet to experience any that outright fail in any manner; they’re generally over-built to handle any possible weight the box can throw at it. But there are a few things which are important to keep in mind. One is the fact that casters are often wet from washing the floor, and they’re constantly bombarded with the solvents, oil, coolant and other contaminants that naturally migrate to the floor. Caster brackets and brake components that are powder coated can prevent corrosion, making them last and look better for longer.

Casters with grease fittings add an additional maintenance component to extend caster life and perhaps my favorite are casters featuring some type of suspension. There’s little this does when a box is just sitting, but if and when you move it around, it makes a world of difference crossing over uneven floor seams or transitions between black top and concrete. It can make the difference between getting stuck or rolling right past, and the heavier the box, the nicer they are to have.

The Work Hutch

One of the more popular features today is a work hutch. It takes the work area on top of your toolbox and converts it into a secure work area. One reason they’ve become so popular is the fact that many of us are using laptop computers on a regular basis, and this eliminates the need to shut them down and tuck them in a drawer.

Most hutches today have power outlets built in, as well as lights. You can also get accessories like shelves and screwdriver racks to hang on the inside, but here’s a real slick option: A half chest. Designed to mount on top of a double- or triple-bay box, it has drawers on one side and a work hutch on the other, combining additional tool storage and a work area.

Horizontal and Side Lockers

If you have a work hutch, you’ve eliminated the possibility of a top box, but a horizontal locker adds valuable space up top. Repair manuals, as well as most blow mold cases will fit in a horizontal locker, and that’s the most common use for them, freeing up space in your toolbox drawers. Side lockers offer the same benefit, with the option of some drawers, and these are nice to hang coats and uniforms too

Side Cabinets

Side cabinets will economically expand your double-bay box into a triple, with multiple available configurations. For a nice touch, most box manufacturers offer trim that can make an added-on side box look like it’s all built as one.

Computer Drawers

This one’s a winner. If want to maximize with a top box, some new bottom boxes offer computer drawers, designed specifically for laptops, complete with power connections. It’s a safe easy way to store your computer.

The Work Surface

Here’s another way to make nice upgrades to a toolbox. Mats or standard top boards can be upgraded to phenolic, stainless-steel or butcher-block tops. These options offer incredible durability, but they also look good, and they’re easy to clean.

Customizable Drawers

This option is one of the more important to consider when buying a toolbox. Most toolboxes come “standard” with a combination of drawers to balance surface area and storage volume. One of the biggest problems you run into is wasted space. You need to have storage volume for large tools or blow molded cases, but space is usually wasted.

When designing a toolbox, you can elect for maximum surface area, which in effect gives you all shallow drawers. If you consider this in the design stage and purchase a horizontal or side locker to store larger items, the additional surface area is worth its weight in gold. TS