The Digital Refrigerant Leak Detector (RLD400) from General Tools & Instruments has been certified by an accredited independent test laboratory to comply with the new American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Halocarbon Refrigerant Leak Detector Standard 173-2012. The instrument has been certified at a leak rate of less than 1 gram per year.

The Digital Refrigerant Leak Detector (RLD400) from General Tools & Instruments has been certified by an accredited independent test laboratory to comply with the new American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Halocarbon Refrigerant Leak Detector Standard 173-2012. The instrument has been certified at a leak rate of less than 1 gram per year.

The new standard was published in December 2012 by ASHRAE to establish a method of testing for qualifying the performance of portable leak detectors designed for the detection of all CFC, HCFC, HFC, HFO and PFC halogenated refrigerant gases. The practices and procedures in this standard cover the testing of refrigerant leak detectors intended for use in the leak testing of refrigerating, air-conditioning and heat-pump systems and their components.

General’s RLD400 is also certified to comply with SAE J2791, J2913 and J1627 standards, and the new European standard EN14624:2012. According to the company, it is the only instrument of its kind to meet all five standards.

The RLD400 offers advanced detecting power and affordability. With its proprietary semiconductor sensor, this instrument is built to detect all commercially available HFC, HFO, HC, HCFC and CFC refrigerant gases, including many new ozone layer-friendly blends, such as R-22 and R-1234yf, approved under the EPA’s Significant New Alternatives Policy (SNAP).

This Made in America instrument is ideal for inspecting and maintaining mobile and stationary air conditioners, refrigerators, chillers and heat pumps, as well as automotive and aviation A/C systems. The RLD400 effectively pinpoints leaks, providing these benefits:

• Prevents compressor, evaporator and condenser damage caused by air and moisture entering a system;

• Saves money by precluding repeated system recharges and inefficient cooling operation;

• Helps large system operators meet U.S. Clean Air Act leak repair timetable standards; and

• Inhibits further depletion of the ozone layer.

Among the RLD400’s best-in-class features are the lifespan of its proprietary semiconductor sensor — more than 300 hours of operation or 10 years normal use — and sensitivities of 0.05 oz./year (1.4 g/year) to R-134a and 0.025 oz./year (0.7 g/year) to R-22. A true mechanical pump draws in samples, which increases sensitivity. Three sensitivity levels let users choose the right level for specific environments. Triple-redundant leak indication — a loud, fast beep; a bright flashing LED; and a relative digital leak size readout — make it easy to identify and characterize leaks in any setting. The RLD400’s automatic calibration and reset ensures accurate leak readings not distorted by ambient levels. In addition, a leak test vial containing a refrigerant sample allows users to easily confirm the instrument is operating correctly. And with its durable construction and padded hard plastic carrying case, the RLD400 is built to survive punishing tasks and harsh environments.

To learn more about General Tools & Instruments and its products, visit www.generaltools.com or call customer support at 1-800-697-8665.

BendPak Founder Don Henthorn Passes Away

Grew company from small machine shop to global leader in car lifts and garage equipment.

Don Henthorn, owner and founder of BendPak Inc., peacefully passed away at home Thursday, March 28, at the age of 85. Under his leadership, BendPak has grown from a small machine shop to one of the world’s leading manufacturers of car lifts and automotive service equipment.

Management and operations of the privately owned company are unchanged.

TS Toolbox Guide February 2024

Here’s a look at some of the core feature and modern frills to consider when it’s time to move into a new office.

Embracing Cutting-Edge Solutions the Industry has to Offer

Embracing cutting-edge solutions is strategic and imperative for technicians navigating the constantly changing landscape of automotive maintenance and repair.

TPMS: Are Retrofits in Your Future?

Installing a retrofit kit can be performed with the tools and equipment you already own and use on a daily basis.

Maximize Your Scan Tool

Are you maximizing your scan tools to their full potential? Don’t let them be just an expensive code reader.

Other Posts

TOPDON USA Makes $25,000 Donation to TechForce Foundation

To date, TOPDON has donated over $66,000 to aid organizations and schools that are dedicated to preparing the next generation of auto technicians around the world.

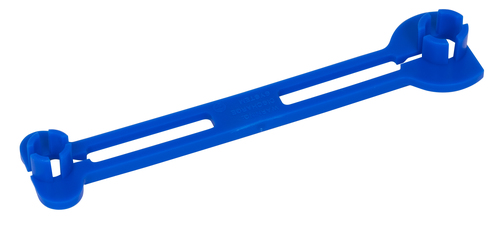

Lisle Low Profile Fuel Line Disconnect

Designed for Ford vehicles with limited clearance between fuel line and high-pressure pump.

Registration Open for ETI ToolTech 2024

The event will be held on April 22-24, 2024 in Newport Beach, CA, at the VEA Newport Beach Marriott.

Dent Fix Soft-Shock Mallet DF-SM76 Reduces Damage

Apply firm precision taps for dashboards, head- or tail-light assemblies, windshield placement, plastic bumper covers, interior or exterior decorative trim, emblems, and GPR/PDR work.