Although stainless steel exhaust systems have reduced the number of exhaust system replacements, it’s important to remember that regular exhaust system inspections remain an integral part of import service. When inspecting an exhaust system, remember that the exhaust pipe and muffler must:

- Help “tune” the engine for peak performance;

- Reduce noise to legal levels;

- Meet current emissions requirements; and

- Safely vent exhaust gases away from the passenger compartment.

If the exhaust fails one or more of these tasks, it’s a candidate for service or replacement.

EXHAUST SCIENCE

Many modern import engines use a “tuned” exhaust to improve the volumetric efficiency of a high-performance engine. The operating principle is simple in concept: When exhaust gases exit the exhaust port at very high velocities, a mild vacuum is created in the cylinder. Engine builders therefore use intake and exhaust valve timing to take advantage of this vacuum effect to increase the intake charge entering the cylinder.

Since most of the torque generated by the combustion process takes place by 90 degrees after top dead center (TDC), the exhaust valve usually begins to open before bottom dead center on the power stroke. The residual combustion pressure in the cylinder is then released into the exhaust port, through the exhaust system, and into the atmosphere.

In most naturally aspirated applications, the intake valve is timed to open a few degrees before the piston reaches TDC on the exhaust stroke. When the piston reaches TDC, both exhaust and intake valves are open, which results in valve timing “overlap.” The mild vacuum created by the pulse of exhaust gas exiting the exhaust manifold and header pipe will accelerate the air/fuel mixture entering the cylinder. This acceleration effect is called exhaust scavenging and is used to a great effect in naturally aspirated engine designs.

Of course, exhaust scavenging is highly dependent upon the engine speed and the overall efficiency of the intake system, camshaft valve timing and the exhaust system. Too much scavenging results in raw fuel being drawn into the exhaust system, which increases hydrocarbon emissions. Too little scavenging, on the other hand, results in poor high-speed engine performance.

DIAGNOSTIC SUMMARY

Engine speed, exhaust gas volume and exhaust gas velocities are the determinants of exhaust system performance. As a rule of thumb, engines operating below 4,000 rpm tolerate a certain amount of exhaust restriction, while engines operating 4,000 rpm and beyond may become very sensitive to exhaust system tuning and gas flow restrictions.

Measuring exhaust system backpressure is one method of analyzing exhaust system performance. Several methods include using a vacuum gauge to measure intake manifold vacuum as the engine is held at a steady-throttle 2,500 rpm. Keep in mind that this method isn’t valid for turbocharged engines because the turbocharger may drastically reduce intake manifold vacuum readings. While there’s no fixed specification, most technicians suspect an exhaust restriction exists when a drop greater than 10 percent of the idle speed reading occurs on naturally aspirated engines.

On both turbo and naturally aspirated engines, the actual exhaust system pressure can be measured by removing an oxygen sensor and inserting a pressure tapping tool directly into the exhaust manifold or pipe. In most cases, the exhaust pressure shouldn’t exceed 2 psi at 2,500 rpm. During a full-throttle road test, 6 psi is the general limit. Of course, it’s important to develop some experience with exhaust backpressure testing before recommending exhaust service to the customer. A technician might find, for example, that engines with mild valve overlap may operate very well at 6 psi exhaust back- pressure. In other applications with increased valve overlap, high-speed performance may begin to suffer at 6 psi of exhaust backpressure.

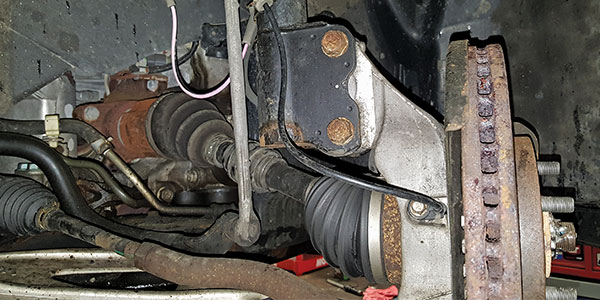

In most cases, exhaust back pressure is caused by the catalytic converter disintegrating and clogging the converter and muffler outlets. In rare cases, a baffle can detach inside the muffler and block the muffler outlet. In other rare instances, the header pipe from the exhaust manifold may be a dual-wall design in which the inner tube has collapsed and has restricted the exhaust. In the most common cases of exhaust restriction, the exhaust pipe has simply been bent or crushed due to minor collision damage.

PERFORMANCE EXHAUST

Since building high-performance import engines has become the latest trend in the import aftermarket, many import shops may receive requests to install tuned exhaust systems. Tuned exhaust headers especially come to mind when dealing with the tuner market.

When selecting a tuned exhaust header for an import vehicle, it’s important to understand that the cheapest header won’t necessarily be the most durable or easiest to install. The most expensive, brand-name units are dynamometer-based and are designed to last many miles. Most use heavy flange materials to prevent exhaust port leakage and may be constructed of ceramic-coated, heavy-gauge steel tubes that will resist corrosion and minor impact damage. In most cases, the brand-name header usually benefits from increased product development times.

When choosing a performance header, it’s important to understand that larger tube diameters are effective only if an engine is highly modified. Smaller tube diameters increase the scavenge effect at lower engine speeds by maintaining high exhaust gas velocities through the header pipe. Increasing the pipe size merely slows the exhaust gas flow, which reduces the mid-range scavenging effect.

Working from the header back, remember that a catalytic converter in good operating condition is usually the least restrictive part of the exhaust system. Most horsepower gains are obtained by installing larger diameter pipe sizes and performance mufflers from the catalytic converter to the back of the vehicle. A 1.500-inch diameter pipe, for example, has 1.767 square inches of area. A 1.625-inch pipe, on the other hand, has 2.074 square inches of area. The 8 percent increase in pipe diameter provides a 17 percent increase in pipe area.

Better still for the installer, some performance exhaust systems may be supplied in the form of kits, complete from engine to rear bumper. In other cases, an installer must hand-bend a performance system. In so doing, he must allow enough body clearance in order to prevent the pipe or muffler from contacting the body panels as it changes dimensions due to heat expansion.

SELLING EXHAUST SYSTEMS

Although the exhaust market is declining on a per-vehicle basis, the exhaust replacement market still offers a low-liability profit center for most import shops. The key to selling exhaust systems, of course, is to listen for excess exhaust noise as each vehicle enters the shop and to visually inspect the exhaust system for external leakage when the vehicle is lifted for service.

Since most exhaust pipe wear occurs at the exterior radius of a pipe bend, the pipe can be tested by tapping it lightly with a ball-peen hammer. A pipe in good condition will produce a slight ringing sound. Most worn pipes will produce a dead, thudding sound as the metal gives way slightly to the hammer blow.

Similarly, tapping a catalytic muffler with a rubber hammer may reveal a rattling noise caused by a loose substrate in the converter. Tapping a muffler along the front or rear bulkhead seam with a rubber hammer may reveal loose baffles or a muffler filled with material from a disintegrating catalytic converter.

When selecting replacement exhaust components, remember that it may be a good time to install an upgraded or a performance exhaust system. In some cases, the system can be upgraded to stainless steel construction, or upgraded in pipe size or muffler capacity. For safety’s sake, remember to include in your estimate new exhaust hangers, clamps, and other hardware needed to adequately support the new exhaust system and hold it in place.

Exhaust Safety Tips:

|