Time has indeed passed you by if you still believe in the traditional import engine tuneup. Many years ago, much of the import service market revolved around the annual spark plug, ignition cable, distributor cap and rotor replacement needed to maintain an import engine at peak efficiency. During the past decade, however, multi-coil waste-spark and coil-on-plug (COP) ignitions have reduced the number of wearing or expendable parts in the ignition system to the spark plugs themselves.

Today, multi-coil ignitions have driven the market into the so-called “100,000-mile” tuneup, which usually consists of a scheduled spark plug and fuel/air filter replacement. In physical terms, the market seems to be drastically reduced. In monetary terms, however, the market has been drastically expanded. Consider, for example, that the dollar value of a long-life, double-platinum spark plug is at least double or triple that of a standard, non-plated spark plug. Consider also that the late-model import engine is packing up to one ignition coil per cylinder, which increases the likelihood of coil failure two- or threefold.

BASIC MULTI-COIL SYSTEMS

Since waste spark ignitions fire only two cylinders per coil, they have the advantage of being able to support increased dwell or saturation times which, in turn, create a higher-voltage spark. This higher spark voltage reduces exhaust emissions and increases fuel economy because cylinder misfires are reduced.

Waste-spark systems are designed to fire a cylinder’s spark plug on both the compression and exhaust strokes of the engine. Compared to single-coil ignition systems, waste spark systems need only the input from a crankshaft position (CKP) sensor to determine when the piston reaches top dead center (TDC) in the cylinder. Most waste-spark ignition coils are mounted in a single assembly called a “coil pack” that may be controlled directly by the engine computer or by an integral ignition control module (ICM).

In some applications, the CKP signal may be sent directly to the PCM or it may be relayed to the PCM by the ignition control module. With either method, the engine computer then calculates the amount of spark advance and the length of saturation or dwell time needed to fire a specific cylinder during the next crankshaft revolution. That information is sent back to the ICM so that the ICM can prepare to fire the cylinder.

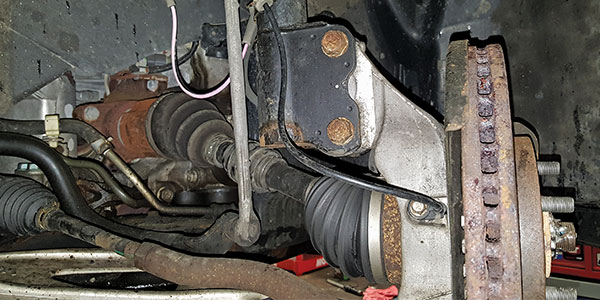

COP configurations are becoming more popular because they eliminate the need for spark plug wires and thus reduce the potential for radio static and spark plug wire failure. Since each cylinder has its own ignition coil, saturation time can be increased for better spark performance and emissions control.

In addition, most COP systems can be directly controlled by the engine computer or PCM, which eliminates the need for an external ICM. COP systems may also require a camshaft position (CMP) sensor, in addition to the CKP sensor, in order to sequence the firing order of the ignition coils.

DIAGNOSTIC SUMMARY

Most coil failures on 1996 and newer imports cause a P0300 series diagnostic trouble code (DTC) to be stored in the PCM’s diagnostic memory. In other words, if a single coil fails on a waste-spark-equipped four-cylinder engine, two DTCs such as a P0301 and P0304 will be stored, which represents the two cylinders supplied by that coil. In direct contrast, a coil failure on a COP-equipped engine will create only a single P0300 DTC.

Waste spark or COP ignitions obviously require different diagnostic equipment and procedures than do conventional distributor ignitions. Consequently, the selection of any diagnostic procedure depends heavily upon component configuration, component access, technician skill levels and equipment availability.

The first step in diagnosing any inoperative coil is to use a professional grade multimeter to test for battery voltage at the ignition coil’s B+ terminal. If no current is available, keep in mind that many imports use a fused circuit or relay to power the ignition system.

The next step is to test the ICM’s or PCM’s ability to switch the coil’s B- terminal to ground in order to saturate the coil’s primary windings. Testing for B- switching can be done by using the duty cycle function found on a professional volt-ohm meter or by analyzing the B- waveform pattern on a shop lab scope. Using a test light to test for the B- switching function can yield erroneous results because the greatly reduced dwell or saturation times used in modern ignition systems may not trigger the light.

Since most conventional ignition scopes can be adapted to waste spark ignitions, the diagnostics can be simplified by analyzing different waveform patterns caused by worn spark plugs, open or short-circuit spark plug wires, high-resistance spark plug wires or weak ignition coils. In addition, the primary circuit waveforms of each coil will yield similar waveform patterns when tested with a conventional lab scope. If you’re not used to waveform analysis, a number of waveform pattern books that do a very good job of relating specific waveforms to specific component failures or operating conditions, are available through different aftermarket sources.

Voltage outputs on each coil can also be measured by using one of several hand-held inductive voltage testers currently on the market. To avoid confusing an issue such as a fouled spark plug with an inoperative coil on waste-spark ignitions, a spark voltage tester should be used with a spark gap tester, such as the old standby “ST-125” tester, installed on the spark plug wire. The ST-125, which is designed to create a potential of about 20-25,000 volts, should be compatible with most modern waste-spark or COP ignition systems.

Most skilled diagnostic technicians often test either the waste- spark or the COP ignition by using a lab scope and current probe to measure the current flow and its rise time through the coil’s primary circuit. Most modern coils draw from seven to 10 amperes of current during the crank or run modes, with the current being limited by the ignition control module or PCM. If the current flowing through a shorted coil winding isn’t limited, the excess current flow may damage the power transistor in the primary ignition circuit.

COP systems pose their own diagnostic issues because their primary circuits may not be accessible for measuring current rise through the coil primary circuit. In some cases, the primary wire isn’t sufficiently exposed for accessing a primary circuit waveform pattern. In these cases, at least one manufacturer supplies an inductive “paddle” that is laid on top of the coil to indicate the availability of spark and spark duration. Another manufacturer supplies inductive attachments that allow its “KV module” to read spark voltage and duration.

WHEN TO REPLACE

Although any coil that tests defective should be replaced, other conditions may exist that also require coil replacement. If, for example, a spark plug wire develops an open circuit on a waste-spark system, the firing voltage may become high enough to perforate the coil housing or to develop a carbon track down the attachment tower for the spark plug wire. In other instances, high firing voltages caused by open spark plug wires or worn spark plugs may exacerbate internal “potting” defects in the coil’s windings and precipitate a coil failure.

COP systems are especially vulnerable to failure because most COP ignitions are designed to fit in an enclosed well built into the cylinder head. Many spark plug well designs can attract and hold moisture, which may cause an external short on the spark plug coil.

In other cases, a carbon track can develop down the side of the spark plug insulator, which will create an identical track on the inside of the coil or coil boot. In either case, the coil may develop an intermittent failure that will cause a P0300 trouble code to be stored in the PCM’s diagnostic memory.

Whatever the case, it’s important to remember that waste-spark and COP ignitions are simply different configurations of the same ignition design that’s been used for many years in import vehicles. When firing voltage exceeds specific values, the insulating properties of ignition coils and other ignition components begin to break down. When this happens, it’s often time to replace one or more ignition coils in the waste-spark or coil-on-plug ignition system.