In 1996, automakers did the aftermarket a huge favor. They added “downstream” oxygen (O2) sensors to their vehicles.

The downstream O2 sensors are located just behind the catalytic converter, or on some Fords, in the converter itself. Unlike the “upstream” O2 sensors that are located in the exhaust manifolds to monitor the engine’s air/fuel ratio, the downstream O2 sensors are used primarily to monitor the operating efficiency of the catalytic converter. This is a requirement of the federally mandated second-generation onboard diagnostics (OBD II) system that keeps a watchful eye on emissions.

Upstream O2 sensors are part of the engine’s fuel feedback control loop, and are necessary to maintain good fuel economy and low emissions. A conventional upstream O2 sensor is essentially a rich/lean indicator that the powertrain control module (PCM) uses to balance the air/fuel ratio. When the fuel mixture is lean (more air, less fuel), an O2 sensor typically produces a low voltage signal (less than 0.2 volts). When the fuel mixture is rich (less air, more fuel), an O2 sensor produces a high-voltage signal of 0.8 to 0.9 volts. The cross-over point where the output voltage suddenly changes from high to low or vice versa occurs when the air/fuel mixture is perfectly balanced (14.7:1).

On some newer vehicles, a somewhat different type of upstream oxygen sensor is used. “Wide-band” air/fuel sensors take the oxygen-sensing technology to the next level. They actually measure the exact air/fuel ratio instead of just giving a rich or lean output signal. The advantage here is that the PCM can now control emissions with even greater precision.

One thing both conventional and wide-band O2 sensors have in common is a need for heat. O2 sensors won’t produce any voltage until they are hot. So inside is a heater circuit that uses electrical resistance to bring the sensor up to operating temperature very quickly. If the heater circuit fails, the sensor may be slow to respond or may cool off and quit working at idle. This will usually set a fault code and turn on the Check Engine light.

On V6, V8 and V10 engines, there are at least one upstream O2 sensor in each exhaust manifold. This allows the computer to monitor the exhaust oxygen from each bank of cylinders separately.

On a scan tool, the output signal from the two upstream sensors is usually referred to as Bank 1 Sensor 1 and Bank 2 Sensor 1. Bank 1 is usually the front bank on a transverse mounted engine. But on a longitudinal V6, V8 or V10, it could be either the right or left bank.

The downstream O2 sensor in or behind the catalytic converter works the same as a conventional upstream O2 sensor, except that the PCM uses its signal to monitor the converter (though the sensor’s output may also play a role in long-term fuel trim adjustments, too).

On a scan tool, the downstream O2 sensors will usually be identified as Sensor 2 or 3.

The PCM compares the readings of the upstream and downstream O2 sensors to see how well the converter is reducing pollutants in the exhaust. When the engine is first started, the downstream O2 sensor’s output will mirror that of the upstream O2 sensor, and flip-flop back and forth between rich and lean. Once the converter lights off, the downstream O2 sensor will settle down and “flat-line” at a steady voltage reading usually around 0.45 volts or so.

If the signal from the downstream O2 sensor continues to mirror that from the upstream oxygen sensor(s), it means converter efficiency has dropped off and the converter isn’t cleaning up the pollutants in the exhaust. This will set a fault code and turn on the Check Engine light when the OBD II catalyst monitor runs. The fix here is to replace the converter, not the downstream O2 sensor.

O2 sensors can be contaminated by silicates from internal engine coolant leaks and phosphates from burning oil. They may also slow down and become less responsive as they age. If the signal lags too far behind the changes in the fuel mixture, or stops altogether, the PCM won’t be able to maintain the correct air/fuel ratio. The engine will usually run rich, and the PCM may set one or more O2 fault codes and turn on the Check Engine light.

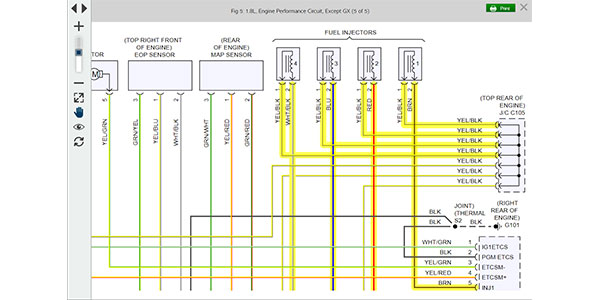

The presence of an O2 sensor code, however, doesn’t always mean the sensor has failed. The fault may be in the wiring, the heater circuit or something else that is causing a rich or lean fuel condition. Accurate diagnosis, therefore, is essential to avoid replacing O2 sensors unnecessarily.

Replacement O2 sensors may be “exact fit” (same connector as the original) or “universal” (which may require cutting and splicing the wires to the original connector).

Because O2 sensors are located in the exhaust system, they may be difficult to remove because of corrosion. An O2 sensor customer may therefore need a special O2 sensor socket, some penetrating oil or a propane torch to loosen and remove the old sensor. He may also need a thread repair kit if the threads in the manifold are damaged when the old sensor comes out. Anti-seize is recommended on the threads of a new sensor to make removal easier next time. Other maintenance items that may be needed include spark plugs, plug wires, filters, PCV valve, etc.