I recently read a book about a pair of deep-sea divers who discovered a German WWII submarine off the east coast of the United States. After meeting its demise, it had settled on the bottom approximately 250 feet below the surface.

It was one of the best books I ever read, and I learned a lot more than I expected as I sped my way through the pages. It turns out that deep-sea diving is one of the more deadly sports that one can become involved in. As a matter of fact, several divers perished while diving on the wreck.

The difference between life and death in this clearly precarious sport is all in the hands of the divers, and the main factor that keeps them safe is extreme organization and careful planning.

Now, if you are wondering what in the world this has to do with automotive tools, well, nothing. And you’re clearly not going to die if you’re disorganized, but it brings us to the topic at hand. Organization and careful planning are without question the foundation of what makes a great technician, and organization in particular is an aspect of our jobs that is all too often overlooked.

Why it is overlooked, I’m not sure, but my guess is that it may be because it takes a lot of time and money, two things that all of us always seem to be short on.

As technicians, our efficiency is the most important aspect of our job, and our efficiency is a direct result of our organization.

Over the last few years, the tool industry has experienced considerable growth on the side of organization, and while some of it has been focused on the larger scale of dealerships and corporate shops, the main focus is still on an individual technician level.

As technicians, our efficiency is the most important aspect of our job, and our efficiency is a direct result of our organization. There are two different angles I want to look at here. First, what I’ll call the dimensional side, our tools and toolbox layout; and second, what I’m going to call the functional side, why we put them where we do.

The Dimensional Side

It is obvious that we keep the same types of tools in certain drawers. For example, the socket drawer, the wrench drawer, the plier drawer, etc. and I don’t know anyone who’s ever strayed too far from this overall layout. It’s kind of a no-brainer of basic organization; this type of layout simply makes sense.

Most of us have a division between metric and standard, often it’s one on one side and one on the other, or perhaps different drawers, but much of your layout also depends on the size and configuration of your toolbox.

Sockets are always a challenge and it’s common to have them all in one drawer utilizing socket storage that holds them upright, so they are easy to access and stay in place. This is a great layout and keeping them tightly lined up side-by-side is the best use of space, but the drawback is that many of us end up using a deep drawer because it is the only drawer that 1/2-in. sockets fit in when they are standing upright.

The problem can be that 3/8-in. and 1/4-in. sockets, even the deep ones, don’t need the same depth as the 1/2-in. sockets, so even though organizationally it makes sense and they all look great in the same drawer, there is space that is wasted. Maybe there’s nothing that can be done about it but hold that thought for now.

Wrenches, pliers, ratchets and extensions also see a myriad of different organizational products and challenges that we try to overcome, sometimes without complete success. It seems that every different one, while successful to a certain degree, also has its drawbacks.

Two organizational products of recent years that have unrealized potential are the foam cut-out system and the grid system. They focus on maximizing the dimensional use of space. The foam cut-out, in my opinion, is just really cool. It has an indisputably professional look, does a flawless job of holding tools in position and you can see if anything is missing at a glance.

Is there a drawback to foam cutouts? As impressive as these systems are, if there is, it would have to do with adding and replacing tools (particularly when the new one is not the same exact size and shape), and ultimately the overall utilization of space. While I’ll always think it’s the cleanest, neatest setup you can have, it does spread things out and takes up space. The more real estate you use, the bigger the toolbox you need.

I certainly have no opposition to monster toolboxes, but generally there just isn’t room in a lot of shops for really big boxes and certainly not room for you to roll in two or three of them. You’ve got to maximize the space you have. If you’re using every square inch efficiently and then you need to move up to a bigger box, it’s easy to justify. As any experienced technician knows, your toolbox and its layout are some of the most important parts of your day-to-day work, but it’s important to maximize your investment by utilizing the space as best as possible before deciding to move up in size.

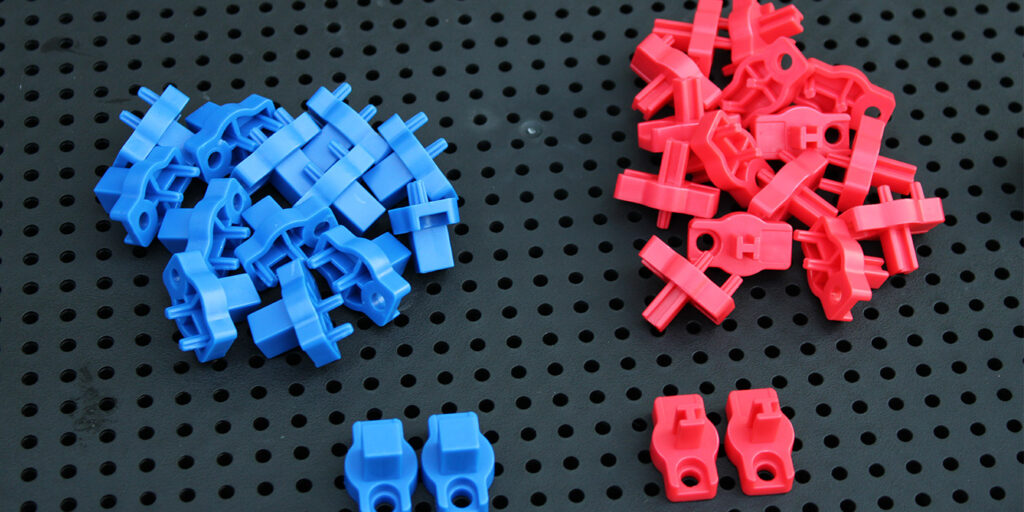

Now, onto the grid system. If you’re not familiar with it, it’s basically a board, filled with holes, that lays in the bottom of a toolbox drawer. Multiple different fittings are available that screw into any location you choose on the board. It’s kind of like Battleship for toolboxes — my 17 mm 1/2-in deep impact socket is located at H-15 … not really, just a little tool humor.

Anyhow, the grid system is pretty cool as well. Each of the individual fittings secures onto the board with a screw and the fittings are designed to hold sockets, ratchets, extensions, pliers, wrenches, small parts containers and more, with color coding for both metric and standard. The grid system can take a long time to set up, but if you really spend the time and refine it, you can maximize space inside a drawer like you have never imagined.

So why are we so fired up about organization? Every tool that rolls around or slides around is one that you have to search for when you’re mid-job. Every second you lose looking for a tool can translate to minutes on the job. If you can’t find the tool you need, the one you know is there, or should be, you start looking through your box, then the workbench, then your tool cart, all the while losing your concentration and momentum on the job. It’s just frustrating and inefficient.

The Functional Side

Why specifically do we put tools where we put them? Part of it is again the dimensional side, our toolbox and the space we have, but to put a light on the functional side, let’s go back to the socket example. Let’s say we have all of our sockets stored upright in the deep top drawer of our toolbox. It works great and looks great, but we know ultimately there’s a lot of wasted space.

In the same toolbox, we utilize another drawer for pliers. We have a plier storage rack, but only some of the pliers fit in it. Some are too wide for the rack, and some, when placed in the rack, are too tall for the drawer. Even though the plier rack offers great organization for some, we still end up with a bunch of pliers that are stacked on top of each other and when we need a pair, we have to dig, a simply inefficient process.

So, what is a possible solution? A common trend with experienced technicians is utilizing an additional tool cart or toolbox of the single-bay style that you can roll around easily to where you are working. If you organize this box with the tools you use the most, it means fewer trips to your big box. If you really think about it, the tools that you use the majority of the time are a very small percentage of the tools you own.

As an example, these are usually a few select screwdrivers, a few select ratchets, maybe your 1/4-in. and 3/8-in sockets, some certain wrench sets and air tools. There are certain things you don’t use every day like tamperproof torx sockets or twist sockets, flare-nut crows foot wrenches, snap ring pliers and an endless list of the specialty tools we all have.

If you separate the tools you use the most and keep them in a smaller, portable box or tool cart, it will allow you to maximize the space in your main toolbox. Using the socket example, if you move your 1/4-in. and 3/8-in. sockets to a tool cart, you open up a lot of space in the large top drawer of your toolbox. Then you could utilize the space to store all of your pliers on their side, tucked closely together.

In turn, you utilize space that was previously wasted, clean up the disorganized pile of pliers and open space in another drawer.

There’s no doubt that in-depth organization and the process of recreating your toolbox layout is like a can of worms combined with a snowball effect. It’s not easy; it’s really a practice of patience and planning. The best plan is to think it out, make some notes, decide what tools in what locations will benefit you the most, decide what the best organizational system will be and then implement your plan. The certainty of all of it is that you’ll have no regrets.