While rise and descent times are important numbers to consider when selecting a vehicle lift, other features that speed up the setup process can have an equally significant impact on boosting shop productivity. Mach series mobile column lifts from Rotary Lift not only raise vehicles faster than comparable mobile column lifts, but they are also built to maximize operator efficiency and reduce downtime, says the company.

While rise and descent times are important numbers to consider when selecting a vehicle lift, other features that speed up the setup process can have an equally significant impact on boosting shop productivity. Mach series mobile column lifts from Rotary Lift not only raise vehicles faster than comparable mobile column lifts, but they are also built to maximize operator efficiency and reduce downtime, says the company.

“When designing the Mach series of mobile column lifts, we studied every step of a typical technician’s setup process and found ways to save valuable time,” says Doug Spiller, heavy-duty product manager for Rotary Lift. “The features that make the lifts so easy to use, when combined with their fast rise times, can improve technician productivity by more than 30 percent. That means shops using Mach mobile column lifts will be able to complete more jobs in a day than they would if they used other lifts.”

Each column in a Mach series mobile column lift is equipped with identical patent-pending controls, so the technician can operate the entire lift from the column that is most convenient. The easy-to-understand control panel features an intuitive graphic layout of the column setup with a vehicle illustrated for reference. When setting up the lift, the technician simply positions a column, turns it on and presses the button that corresponds to the column’s position on the control graphic. LEDs show the power, synchronization and status of each column. When all LEDs are green, it means the columns are synchronized and ready for lifting. There is no RFID wand to lose or complicated programming procedure to memorize.

When moving a Mach series lift, the technician does not need to pump up the columns as required with pallet-jack steering systems. Springs located at each wheel lift the column when the vehicle reaches the ground, allowing the lift to be moved. When loaded, automatic brakes keep the column from moving on sloped floors without the need to manually lower the lift. These features are standard and easy to use, while pallet-jack systems can leak and be costly to repair. Since most lifting jobs require four to six columns, the automatic spring-loaded steering system saves considerable time and effort during setup.

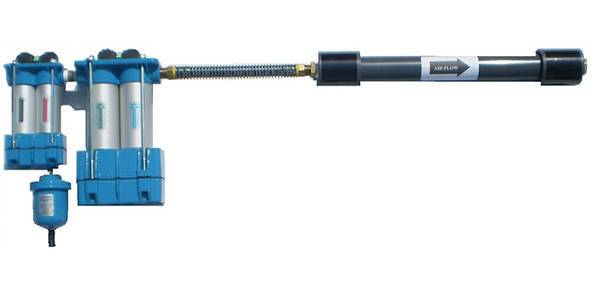

The hydraulic cylinder in each Mach series mobile column is uniquely positioned to prevent it from being damaged. The cylinder is inverted, so the chrome piston rod remains protected from debris and damage at all times. The only part of the cylinder that is ever exposed is the casing. According to the company, on other hydraulic mobile column lifts, the piston rod is exposed at the base of the column as the lift is raised. Even chrome piston rods are susceptible to corrosion and damage. Shop debris can stick to the rod and damage the seal, necessitating more frequent repairs.

“Mach series mobile column lifts are easy to move, synchronize and maintain,” says Spiller. “Since there is very little installation, they can be seamlessly added to any shop and put into immediate use. Technicians will be happier and more productive.”

Rotary Lift Mach series mobile columns can be purchased in sets of two, four, six and eight, with either 13,000 lbs. or 18,000 lbs. of capacity per column. The wide range of combinations ensures a perfect fit for any lifting need. With a 12,000 lb. capacity truck frame adapter kit, two 13,000 lb. capacity columns can be used to service popular Class 2 and 3 pickups, while six 18,000 lb. capacity columns will lift nearly anything on the road. The columns are battery powered, so they can be used throughout the shop.

To learn more about the Mach series of mobile column lifts, contact your local Rotary Lift distributor, visit www.rotarylift.com or call (800) 640-5438. You can also find Rotary Lift on Facebook, www.facebook.com/RotaryLift; Twitter, twitter.com/RotaryLift; and YouTube, www.youtube.com/RotaryLiftMedia.