1. ROTORS WARP: Rotors do not warp. In the 1970s, someone came up with the whole “warping” theory and it has stuck. Why? Because to the layman, it makes sense. But, in reality it is a false explanation that does not hold water. Warping is actually two verifiable phenomenon that can be experienced individually or in combination. Neither of these have anything to do with warping. These phenomenon are Brake Torque Variation and Disc Thickness Variation.

1. ROTORS WARP: Rotors do not warp. In the 1970s, someone came up with the whole “warping” theory and it has stuck. Why? Because to the layman, it makes sense. But, in reality it is a false explanation that does not hold water. Warping is actually two verifiable phenomenon that can be experienced individually or in combination. Neither of these have anything to do with warping. These phenomenon are Brake Torque Variation and Disc Thickness Variation.

Brake Torque Variation (BTV) is a variation of torque across the face of the rotor causing the rotor to slip and catch as brake pads pinch the rotor. The differences in torque across the rotor may be caused by an inconsistent rotor finish or the metallurgy of the rotor.

BTV can be caused by uneven deposits of friction material. This might not cause a pulsation in the pedal, but it will cause the vehicle to judder or vibrate.

The second element of warping is Disc Thickness Variation (DTV). This measurement is the result of measuring the thickness of the rotor surface at multiple spots around the rotor. Subtract the thickest part from the thinnest, and you will have a measurement for DTV.

As the thickness variations of the rotor pass through the caliper, the piston moves in and out. This action generates pulsations in the brake pedal that can be felt by the driver.

Very small amounts of DTV can create a significant problem. Today, new vehicles are typically built with a thickness variation of less than 0.00078”. Thickness variations in excess of 15 microns (0.00059”) can easily generate driver complaints. DTV specifications are significantly lower than runout specifications which typically are .002”. This is due to the fact that a caliper can “float” or move back and fourth without forcing the piston back into the bore.

Very small amounts of DTV can create a significant problem. Today, new vehicles are typically built with a thickness variation of less than 0.00078”. Thickness variations in excess of 15 microns (0.00059”) can easily generate driver complaints. DTV specifications are significantly lower than runout specifications which typically are .002”. This is due to the fact that a caliper can “float” or move back and fourth without forcing the piston back into the bore.

So what causes BTV and DTV? The answer is not distortion caused by overheating. Heat does play a role as it increases wear on the rotor that causes a “warped” feeling.

2. THE MORE LUBE MEANS LESS NOISE: Basting a set of pads or caliper slides in lubricant, no matter how expensive it is, will not not solve a noise issue for an extended period of time. Why? Because the excess lubricant can melt or some chemicals can flash off. The melting lubricant can find its way on to the pads causing a judder problem and longer stopping distances.

Excessive lube can also attract debris and dirt. As the lube hardens over time, it turns to a concrete like substance that causes slides and calipers to stick. If excessive lubricant finds its way onto the caliper piston’s boot, the lubricant will attract metal particles that can destroy the rubber.

Excessive lube can also attract debris and dirt. As the lube hardens over time, it turns to a concrete like substance that causes slides and calipers to stick. If excessive lubricant finds its way onto the caliper piston’s boot, the lubricant will attract metal particles that can destroy the rubber.

Shims need only a small amount of lubricant. Some floating one-piece and two-piece shims only require a small amount of lubricant between the surfaces of the shim and pad. There is no need to coat the entire back of a brake pad with a lubricant.

For the caliper anchor pins, use a silicone-based brake grease. Make sure it is compatible with all rubber compounds including nitrile, Teflon, nylon and other synthetic rubbers. For the shims, abutment clips and slides, use a synthetic-based boundary-type lubricant that has a high solids content and typically contains a variety of friction-reducing ingredients, such as molybdenum disulfide (moly or MOS2) and graphite.

3. ALL PADS ARE THE SAME: One of the greatest myths out there is that some customers will not use the full potential of a brake pad due to their driving style or commute. This is false because the one time the customer needs to use the full potential of the pad, the performance will not be measured in dollars and cents, but inches and feet.

3. ALL PADS ARE THE SAME: One of the greatest myths out there is that some customers will not use the full potential of a brake pad due to their driving style or commute. This is false because the one time the customer needs to use the full potential of the pad, the performance will not be measured in dollars and cents, but inches and feet.

What standards should you have when selecting replacement brake pads? Try them for yourself! Set aside some time when the shop is not busy or on a weekend to try out the brands of brake pads you install. Perform at least four emergency stops from 55 mph to a dead stop back to back. Let your right foot be the judge.

4. SHIMS ARE NOT REQUIRED: One of the greatest mistakes made is not installing shims on a new set of pads. On new vehicles, the shims are designed along with the caliper and pads. Shims are not a last minute "add on" to make sure the pads fit, they are a critical part making sure the brakes operate sufficiently and quietly.

4. SHIMS ARE NOT REQUIRED: One of the greatest mistakes made is not installing shims on a new set of pads. On new vehicles, the shims are designed along with the caliper and pads. Shims are not a last minute "add on" to make sure the pads fit, they are a critical part making sure the brakes operate sufficiently and quietly.

More and more OEMs and aftermarket brake pad manufacturers are using single and two-piece shims that clip on to the front in-board and outboard pads. This design creates a “boundary layer” preventing vibrations from being transmitted to the caliper and knuckle. They can also prevent heat from being transmitted to the piston. Shims should always be replaced.

5. ALL ROTORS ARE THE SAME: A rotor can fit on a vehicle and still not be the right rotor for the vehicle or driver.

The wrong rotor that fits may develop runout, BTV and DTV sooner than a quality rotor. Also, low-quality rotors may have compromises in the structure and metallurgy that may make sense to the wallet, but not the driver.

The wrong rotor that fits may develop runout, BTV and DTV sooner than a quality rotor. Also, low-quality rotors may have compromises in the structure and metallurgy that may make sense to the wallet, but not the driver.

6. NEW ROTORS NEED TO BE MACHINED: New rotors are supposed to be finished to specifications and ready to install out of the box. There should be no reason to give them a “clean up” cut. If they do need a cut, you need to find a different rotor supplier.

A recent Babcox survey found that 35% of our readers are still machining brand new rotors before they install the rotors on their customers’ vehicles. Machining new rotors shortens rotor life. It may also leave a rougher finish on the rotors than the factory finish.

The manufacturing tolerances for rotor runout on most new rotors average about 0.001 inches or less, with a maximum upper limit of 0.004 inches. Some cars are unusually sensitive to rotor runout. As little as 0.0015 inches of runout on these cars may produce noticeable pedal pulsations.

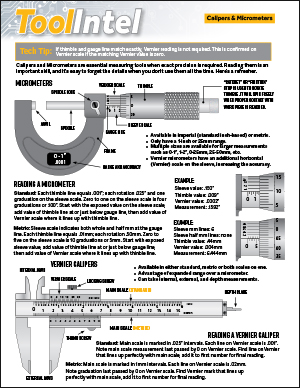

7. DIAL INDICATORS AND CALIPERS DO NOT EXIST: Some shops assume that measuring rotors can be done with the naked eye and measurement tools do not exist or are not affordable. This myth is not true.

7. DIAL INDICATORS AND CALIPERS DO NOT EXIST: Some shops assume that measuring rotors can be done with the naked eye and measurement tools do not exist or are not affordable. This myth is not true.

If your shop does not have a dial gauge and a set of micrometers to measure rotor thickness, you should not be performing brake pad or rotor replacements.

In 2009, three states used rotor thickness measurements to convict shops and chains of fraud for replacing parts unnecessarily.

If you have these tools and do not use them, you should get out of the brake business.

8. YOU DO NOT NEED REPAIR INFORMATION TO REPAIR BRAKES: All brake systems may look the same after a while, but it is the unseen that can hurt you and cause a comeback. It might be as simple as a torque specification for a caliper bracket or as complex as a disarm procedure for an ABS system. You need to have access to current repair information. Information can pay for itself by saving time and preventing a comeback.