By Mitch Becker for BodyShop Business

By now, most of you have heard the news that Ford has mainstreamed rivet bonding with the introduction of the 2015 F-150. This has forced many shops to look into some new equipment, such as self piercing rivet guns (or SPR guns). The cost of this gun has many shop owners shaking their heads and wondering if it’s worth buying. I can’t answer for you or your shop, but as a technician who plans on working on Ford and other aluminum vehicles, the SPR gun is a necessary purchase.

Mainstream

Although vehicle manufacturers such as Tesla, BMW and Jaguar made rivet bonding a specialized process, the introduction of the F-150 brings the SPR gun and rivet bonding to mainstream repair.

Automobile manufacturers have historically used multiple squeeze type resistance spot welds (STRSW) during assembly. Today, consumer demand has driven automakers toward stiffer and quieter vehicles. Weld bonding or STRSW and adhesives used together have met many of these demands.

The success and use of adhesives is becoming more widespread. The drawback of adhesive only is they typically have poor peel strength, which compromises vehicle crash performance. This requires a mechanical attachment to compensate.

This brings rivet bonding to a whole new light. As vehicle manufacturers look to hybrid vehicle construction to decrease weight in new vehicles, rivet bonding makes some possibilities a reality. Traditional fastening methods, such as riveting by itself and welding, are often inappropriate for joining dissimilar materials.

Although rivet bonding is not a new technology, it has been a little-used process until recently. BMW, Jaguar and other vehicle manufacturers used rivet bonding to join a steel structure with an aluminum structure. The success of bonding these two dissimilar metals together has led the way to new possibilities.

The Process

In the rivet bonding process, the adhesive is the primary joining mechanism providing the stiffness and noise, vibration and harshness characteristics. The rivets become the primary mechanism during a crash event when the adhesive would normally peel.

To understand some dynamics of how it works, rivets alone can hold two metals together. If we were bonding steel to steel, movement and fatigue along with corrosion would be issues. If bonding two dissimilar metals, we would have to include galvanic corrosion of metals as an issue as well.

Rivet-only disadvantages include:

- Rivets can gradually loosen under extreme vibration and cause panels to rattle

- Rivets cause point stresses, which can lead to fatigue and cracks

- Rivets are time-consuming and expensive to use

Rivets add significant weight and normally need heavier gauge metal, which again adds weight.

Structural adhesives offer many benefits, which can overcome these problems. They include:

- Better distribution of stress and reducing the possibility of fatigue

- Can both seal joints and bond materials for optimum corrosion protection

- Protect contact of dissimilar metals

- Don’t gradually loosen

- Cost effective and fast to apply

Compared to joints made only with rivets, rivet bonding offers additional benefits such as:

- Continuous, leak-tight joints

- Higher-strength joints

- Increased joint stiffness

- Improved peel and impact resistance, improving crash characteristics

There is one other factor that must be considered: heat, the Achilles heel to many construction materials. Rivet bonding allows for a cold joint process which negates the adverse heat effect on materials – although some materials do allow for limited heat during construction and repair. But the rivet bonding process does not cause heat issues.

Not So Easy

Although it all sounds easy, there are some things that repair centers need to be aware of. Rivets sound easy, but there are procedures and disciplines that must be followed.

Vehicle manufacturers’ instructions must be followed. Although the repair procedure may be different from the factory build, deviation from instructions could be a source of liability and result in warranty issues or injury to a valued customer.

Rivet bonding procedures will vary in the use of adhesives. The preparation of mating surfaces would be an example. The Adhesive Bonding course, along with ALI01 and FOR06, are excellent sources for information.

A factory may use rivets, clinches, bolts, welds and/or a version of threaded fastener called a flow drill screw. Knowing the rivets or fastener to be used for repairs is critical to being sure all parts will correctly reassemble. A gasket may not fit over a rivet with a large protruding back. Be sure that the material the rivet is made of is what is required for strength and compatibility.

Using only the recommended fasteners is the best practice. Some rivets will require a hole through two or more pieces to be bonded. SPR rivets press through metals to be bonded. Communicate with technicians and consult manufacturers’ guidelines to see which is required for the repair process.

Rivet Types

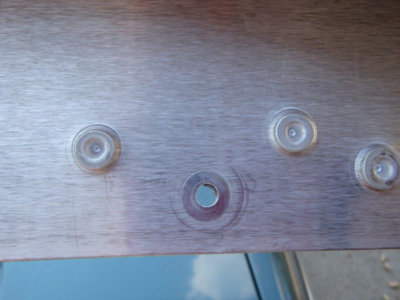

The most common rivet being used for newer vehicles, particularly aluminum ones, is the SPR. This steel fastener has a tin/zinc coating to prevent galvanic corrosion. The rivet pierces the top sheet and forms within the lower sheet but does not penetrate it. This requires the use of a special tool that requires access to both sides. The advantage of this tool is it also can remove the SPR, although this again also requires access to both sides. Once the rivet is removed, there will be a hole in both pieces. This may require a different rivet to reassemble. There is no hole when using SPR.

Another rivet would be a solid rivet, which goes through a hole and is pressured to fit into an opening. The most common is a shouldered rivet to 100deg. The hole must be dimpled or recessed to the same for a flush fit. A press with built-in bucking bar or pneumatic tools such as an air hammer and bucking bar will be used to make a bucktail on the backside of the rivet. Access to both sides is a necessity.

Blind rivets such as hemlocks and monobolts are used when access to the backside is limited. The hemlock is a rivet that pulls two panels together. The hole is a required diameter and is not loose when the rivet is installed. Oversized holes will require the monobolt, which expands radially to fill the hole and seal the panels. Both require a hole through both panels.

This is a simple explanation of the rivets and their uses. I encourage all repairers to take the I-CAR classes to learn more. Removal and installation concerns are a whole different article. I wanted to give a shop manager or owner some simple things they must know and impress upon them that they must make sure all technicians follow the procedures. As with all new things, never assume your techs know what to do. Follow up and verify all expectations.

Small Details

With more vehicles made from a variety of materials slated for construction, rivet bonding will become more common. Knowing procedures and where to find training is important to shop success. When working with aluminum or other materials that have special precautions, follow those precautions diligently. Sometimes the smallest detail can create failure.

Keys to Successful Rivet Bonding

- Know where to find instructions, be it from the manufacturer or another OEM data source

- Follow instructions

- Use fasteners provided (many are supplied with the part)

- Know your rivets

- Panel fit is crucial; like welds, there’s no room for error

- Have the proper tools

- Use the correct adhesive

- Prepare all mating surfaces according to the manufacturer

- Wait/cure time

Mitch Becker is a technical instructor for ABRA Auto Body & Glass. Contact him at (763) 585-6411 or [email protected].