This article will document Diagnostic Trouble Code P0420 — Catalyst Efficiency Below Threshold. This code involves the integrity of the catalytic converter. This is a code that many have encountered, but once in a while you run across one that requires mention.

This story begins based on a simple concept, the vehicle being tested is in an emissions state that requires all monitors on the vehicle to run and pass. Our subject vehicle is a 1998 Cadillac Eldorado. All monitors on the vehicle have run and passed except the catalyst monitor. The repair facilities in the area have advised the customer to keep driving the vehicle so that the enable criteria can be met and the monitor run. Once the criteria are met, the monitor can then run and hopefully pass.

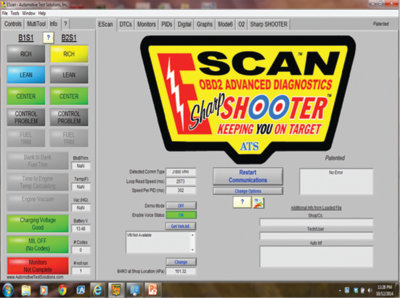

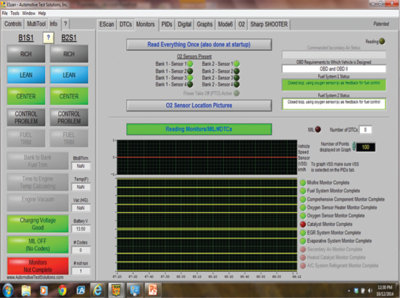

Figures 1 and 2 denote what was witnessed when the vehicle was scanned with a generic scan tool. The pictorials show that the MIL is not commanded on; all monitors have run except for the catalyst monitor. By this time, the Eldorado has been driven for well over a month.

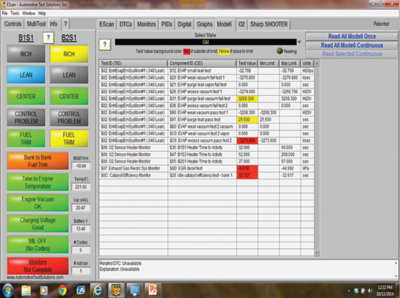

A review of mode 6 data per our scan tool shows a concern toward the catalyst monitor. It appears it is run at idle on this vehicle. Figure 3 shows the mode 6 data in reference to this vehicle.

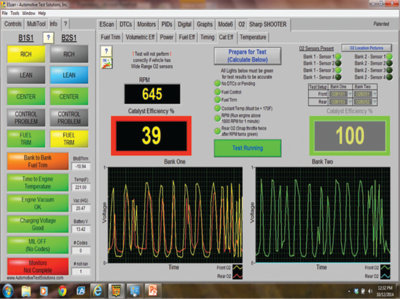

I decided to use one of the features of this scan tool — it has an option available to run a catalyst efficiency test at idle, but will not set a flag for the catalyst monitor. Our goal at this point is to get an opinion as to whether the catalytic converter is efficient or not. The catalyst test is run and it shows an efficiency rating of 39%; this is no doubt a failure status. Figure 4 shows the test results.

It is interesting again to note that the catalyst monitor did not run on this vehicle, the question is “why not?” If a catalyst has degraded to the point where it no longer meets the compliance of OBD II standards, why did the monitor not run and fail this component?

A little research is needed to answer this question. I begin by going to a General Motors website that allows me to review limits for mode 6 data as well as failure criteria for this monitor based on year, make, model and engine family. The data shows a mode 6 range of -32.768 to +32.767 seconds. Our actual mode 6 data showed a value of +32.727 seconds. This was the reason for the red flag noted per the actual mode 6 data we reviewed for this vehicle.

I then proceeded to review failure criteria as well as time and frequency of this test. My review of failure criteria indicates that the system looks at “oxygen storage capacity” (OSC) to verify if the catalyst meets compliance, the table below denotes the data obtained. It is interesting to note that up to six tests per trip (EWMA) can be run in order to set the catalyst flag.

| OSC Time Difference (pass) | Time and Frequency |

| Greater than 0.12 seconds | Max of 6 tests per trip (EWMA) |

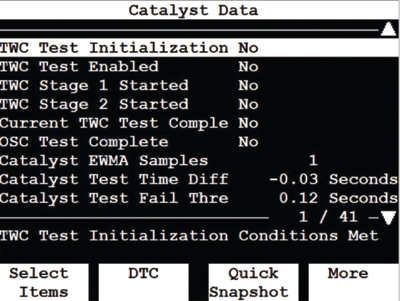

I then decided to review scan data from a Tech 2 to see if it offered additional information in getting some questions answered. Figure 5 shows the catalyst data for this vehicle.

A review of the catalyst data list shows one sample for EWMA. The test value needs to be greater than or equal to 0.12 seconds, but the actual test result was -0.03 seconds (failure). If the data was somewhat consistent in reference to these values, the catalyst monitor flag should at some point set and fail the monitor.

A review of the emission test results two years prior shows that the catalyst monitor did not run at that time as well. It is the opinion of this observer that we should now check to see if any software updates may exist for this vehicle.

A review of software calibrations shows that there is a reflash for catalyst response for our vehicle. The vehicle received a reflash and our goal was to allow the OBD II system to do its job, the monitor did run and fail. A code P0420 was stored in the controller’s memory. The catalytic converter was replaced with an OBD II-compliant converter and the monitor was rerun. The monitor then ran and passed.

This Pulling Codes case is now solved.