I recently saw a post from a shop owner on a technical help forum who was having a problem finishing up a transmission R&R. The car was back together, but the transmission was not communicating with the engine control module. The transmission control module was inside the valve body and needed to be programmed for the vehicle so it could communicate.

This was no novice tech. Previously, he was able to solve a similar issue with a scan tool that could perform some limited programming. But this time, the module on the remanufactured transmission needed to be reflashed and reprogrammed on the vehicle to complete the job.

In the thread of the forum, shop owners were exploring the options to get the vehicle back on the road. Some suggested he find a local service that could program the car, but his shop was in a very rural area. Others said he should remove the valve body and ship it to a service that could perform the programming.

Other members said maybe it was time for the shop to invest in training and tools to do programming and reflashing on site.

The choice to reflash is the hardest because there is no one solution or single path to follow. No matter how many training classes you attend or magazine articles you read, it is not until you start specing out and purchasing the computer, tools and subscriptions that you realize what you are up against.

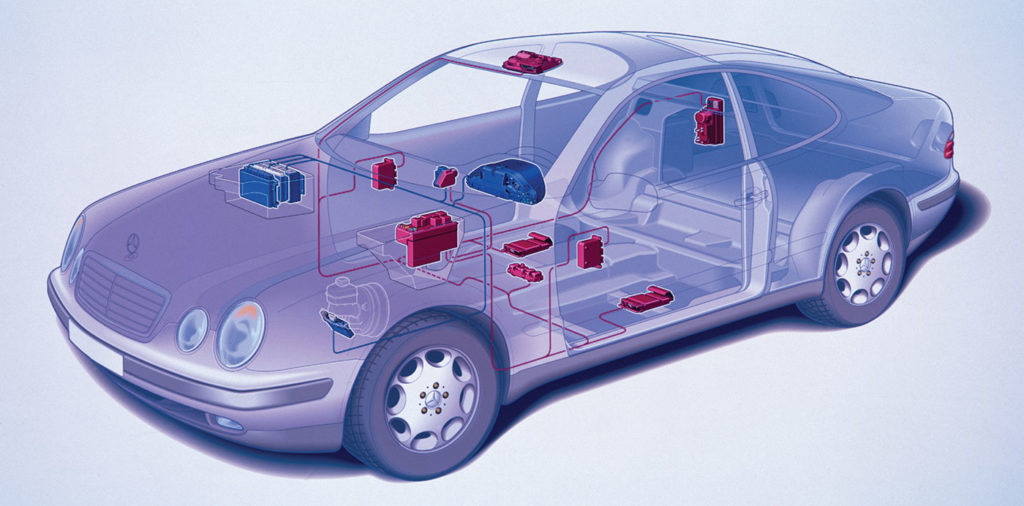

THE COMMUNICATION INTERFACE

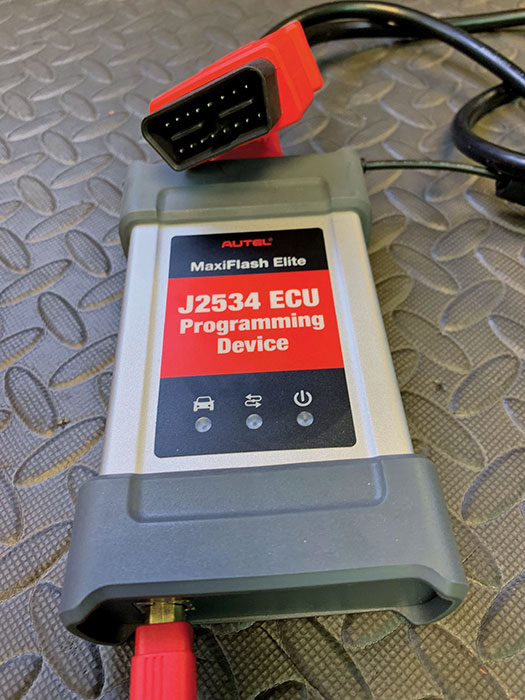

Before you purchase a computer, it is a good idea to select how you plan to connect to the vehicle. Most of all, you need to understand what the interface can and can’t do.

SAE J2534-1 is the protocol for reflashing and reprogramming emissions and engine module calibrations through the generic OBD II port. The SAE, ISO and automakers collaborated to comply with the mandate that emissions calibrations can be updated.

If you need to program a non-emissions module on some vehicles, you might need a vehicle interface that can communicate using SAE J2534-2. But these two communication protocols are not enough for every vehicle or every module. Automakers will also use other communication protocols for other modules and systems on the vehicle.

If you specialize in one make, you might be able to get away with just a USB cable with the OBDII connector on one end. These cables can be very effective for vehicles from one manufacturer because they are hardwired for the OEM’s software. Unfortunately, suppliers do not make cables for every manufacturer.

The next solution is a J-Box. This still connects to a USB port on the computer and the OBDII connector, but in between is an electronics-filled box. The guts of the box switch the pins in the OBD II connector and translate the information from the vehicle and computer. These can handle multiple makes and protocols. With either cable or J-Box, it is critical to look at the coverage and compatibility with the vehicles coming frequently to your shop.

However, each OEMs is still allowed to approve or certify if a cable or J-Box will work with its software and website. You may find that a cable or J-Box will work one day, but the next day there could be problems. When these problems occur, there is support out there from the OEM, tool manufacturer and even online groups of technicians. One of the best sources is a Facebook group called J2534 Discussion for Beginners-USA Only.

COMPUTER

Most OEMs require a Windows-based PC with specific hardware. Depending on the vehicle manufacturer, some specify the computer’s operating system use a 32- or 64-bit version of Windows 10. Most manufacturers have stopped supporting Windows 7.

Most manufacturers call for an “enterprise-grade” computer and access point (Wi-Fi router). It can be difficult to define what enterprise-grade means but in its supporting documents, most define it as hardware intended for businesses. Dell calls it a PC for work. HP calls its line “laptops for business.” The main attributes are better hardware and technical support than consumer-grade computers. If you have questions about your PC, look at the documents on the OE’s website. The reason why they advise this level of computer is to avoid the possibility that the PC has malware or bloatware. The other consideration is cheap PCs come with home versions of Windows.

The other item to consider is the hard drive. Manufacturers including Honda and Ford require that the hard drive needs to be solid-state. Luckily, solid-state drives have dropped in price significantly over the past five years.

Pay attention to the type of USB connections on the machine. The type of port you need to look for is a Type-A port — this is the most common rectangular USB port. If the computer says it only has Type-C ports they will not work with most reprogramming cables. Even if you purchase a USB Type C to Type-A adapter, there is no guarantee it will work.

Type-A ports can be USB 2.0, 3.0 or 3.1. Some reprogramming and reflashing cables will work with USB 2.0, but most require or recommend 3.0 or 3.1. The best way to tell is by the color of the port. USB 2.0 ports are black inside and USB 3.0 and 3.1 ports are blue. USB 3.0 and 3.1 is 10 times faster than 2.0. USB 3.0 can deliver 4.5 watts of power. USB 3.1 can change the wattage and voltage depending on the device. When selecting a vehicle interface device, look at both the device manufacturer’s specifications as well as the OEM’s requirements.

VOLTAGE SUPPLY

Some reflash and programming sessions can last more than an hour. Reflashing voltages can vary from 12- to 14-volts depending on the OEM and model. If the battery voltage drops below a set voltage, the reflashing process will stop and possibly damage the module. Some manufacturers call for a consistent 13.1 volts, but Honda says that a battery jump pack can be used.

Your old battery charger should not be used because these turn the power off and on. There are battery maintainers made specifically for reflashing that can deliver the correct voltage and amps during a procedure. Check the OEM’s website for information on the equipment about maintaining the battery. It is best to invest in a battery maintainer made for reflashing before starting to reflash process.

SUBSCRIPTIONS

You will need to subscribe to the OEM’s service information website. Subscription fees vary by OEM and have several payment options. Make sure you write down your logins and passwords. Before you start reflashing, take the time to register and navigate the OEMs’ websites – bookmark the essential pages on the sites in your browser.

TIME

You will not be able to perform flash reprogramming straight out of the box. It takes time to set up the computer and register at the OEM websites, so on a slow day, take some time to experiment on shop vehicles. There is nothing worse than having to wait for a verification email from an OEM to just start up the subscription. Learn before you burn.

This article was originally published in ImportCar: https://www.import-car.com/pc-reflashing-and-reprogramming/