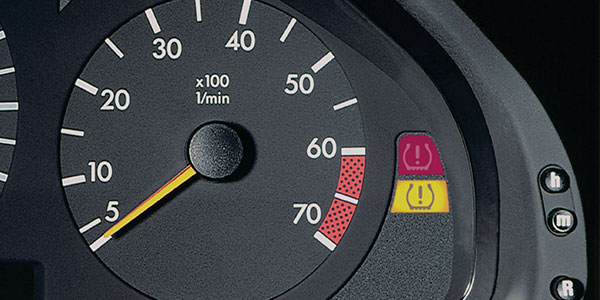

Tire Pressure Monitoring Systems have been phasing in for more than a decade — with some systems dating back to the late 1990s (such as Corvette) — and are now required on all new passenger cars and light trucks. TPMS is a great safety innovation and has likely saved some lives. But TPMS also complicates tire replacement and rotation, and special tools are often required on many applications to reset the system if the tires have been rotated or any of the TPMS sensors have been replaced.

Tire Pressure Monitoring Systems have been phasing in for more than a decade — with some systems dating back to the late 1990s (such as Corvette) — and are now required on all new passenger cars and light trucks. TPMS is a great safety innovation and has likely saved some lives. But TPMS also complicates tire replacement and rotation, and special tools are often required on many applications to reset the system if the tires have been rotated or any of the TPMS sensors have been replaced.

To make matters worse, there’s almost no standardization between the systems, protocols or sensors. A wide variety of different systems and service procedures are used. So if you’re doing tire-related work on late-model vehicles, you need the proper tools for resetting a wide range of tire pressure monitoring systems.

Relearn/Reset Tools

When the tires on a TPMS-equipped vehicle have been rotated from one wheel position to another, the TPMS system has to relearn the new wheel positions. On some applications, the vehicle has an “active drive relearn procedure” that allows the system to figure out which wheel is which automatically. You don’t have to do anything at all and no special tools are required. Unfortunately, these are the exception rather than the rule. The only applications are Dodge, Chrysler and Jeep vehicles.

Most vehicles require some type of “stationary” relearn procedure to reset the system. This requires some type of TPMS tool to activate each of the tire pressure sensors in a specified sequence so the TPMS control module can relearn their new locations. On some GM applications, a J-41760 magnetic tool is required to “wake up” the sensors. On most other applications, a factory TPMS tool or an aftermarket TPMS tool that broadcasts a radio signal is needed for the sensor position relearn procedure.

The limitation with factory TPMS tools is that they typically only work on one vehicle make. Most aftermarket TPMS relearn tools, by comparison, work on a wide range of makes and models. Buying a TPMS tool that has universal coverage will allow you to work on almost any vehicle that comes into your shop. Most of these tools are also updatable via the Internet and a USB port connection. Entry-level aftermarket TPMS tools with basic relearn capabilities typically sell for a couple hundred bucks, while the high-end models with additional diagnostic capabilities and features can cost up to several thousand dollars.

On some applications, the TPMS relearn tool can be connected to the vehicle’s OBD II diagnostic connector to read and clear codes, display system data and perform sensor ID programming. On many Asian and European applications, each individual tire pressure sensor has a unique ID code. If one or more sensors have been replaced, the new ID information has to be input directly into the system. So if you don’t have a TPMS tool that can do this, your only alternative is to send your customer back to the new car dealer to have the ID reprogramming done.

TPMS relearn procedures vary a great deal from one vehicle to the next, so you also need access to the TPMS service data for the vehicle, or a reference manual or chart that covers the relearn procedures. Without this vital information, you can’t reset the system.

Essentially, most relearn procedures require you to put the system into a relearn mode. On some, this may require a command from a scan tool or plug-in TPMS tool. Or, you may have to cycle the ignition key on and off a certain number of times while stepping on the brake pedal. On others, the keyless entry fob may be used to wake up the TPMS module and ready it for relearning.

When the TPMS is ready, it may signal by beeping the horn or flashing the hazard lights. The TPMS activation tool is then placed near one of the tire pressure sensors, and a button is pressed for five or six seconds to wake up the sensor. As soon as the TPMS module recognizes the sensor and learns its position, the system signals again by beeping the horn or flashing the hazard lights. You then repeat the same procedure for each of the remaining tire pressure sensors in the specified order until the relearn procedure is complete.

Sensor Diagnosis

A TPMS tool can also be used to diagnose faulty TPMS sensors. By using the tool to activate each sensor, the sensor’s output signal can be verified. This will tell you if a sensor is working or not. Some tools can also decode and analyze the sensor signal to see if the indicated tire pressure matches the actual pressure inside the tire (which you can check with an ordinary tire pressure gauge).

TPMS tools that plug into the OBD II connector can also display and clear system fault codes, which will be necessary to turn out the TPMS warning light if a fault exists.

Service Kits

If you are replacing tires, patching flat tires or replacing a leaky valve stem on a TPMS-equipped vehicle, you’ll also need a TPMS service kit. These kits include new base gaskets and nuts for the valve stem, and also valve cores and caps. Special nickel-plated valve cores are required to resist corrosion, and special valve caps are required on TPMS valve stems so the cap does not interfere with the signal broadcast by the sensor.

The average life of the battery inside a TPMS tire pressure sensor is about five to seven years, so eventually the TPMS sensors have to be replaced. Most often, this will coincide with replacing the tires when the original tires become worn out. New sensors typically come with new mounting hardware (gaskets and nuts), and a new valve core and cap. You won’t need a service kit for this type of work, but you will need some special hand tools to install the sensor.

TPMS Sensor Installation Tools

One item that’s absolutely necessary to have when replacing TPMS tire pressure sensors that have a valve stem with a nut at the base is an accurately calibrated inch-pound wrench (mechanical or electronic). The amount of torque used to tighten the base nut on a TPMS valve stem is critical. If you don’t get the nut tight enough, the seal may leak and the tire will lose air. If you overtighten the nut, you risk damaging the seal or valve stem, which would also cause an air leak.

Typical torque values for the base nuts on a TPMS valve stem range from as low as 35 in.-lbs. of torque to as much as 80 in.-lbs. of torque. That’s quite a range. This does not mean that any torque value within this range is acceptable. No, it means that the torque specifications for the base nut on one car might require 44 in.-lbs. EXACTLY, another might require 62 in.-lbs. EXACTLY, another might specify 71 in.-lbs. EXACTLY, and so on. Don’t guess. Look up the torque specifications for the vehicle you are servicing to make sure you use the correct torque.