In the shop today we have a 2000 Volkswagen Jetta with a 2L turbo engine. The owner stated that the car doesn’t start and I think it might have broken timing belt. So today we’re going to walk through the process of diagnosing a broken timing belt or broken timing chain, and talk about what that really could mean for the engine.

A timing belt is a vital part of an engine. It makes sure that the crankshaft and the camshaft stay in time. In an engine like this, failure can and usually does result in severe engine damage.

This and many other engines are known as interference engines.

When operating correctly, the piston and the valve occupy the same space but at different times. When a timing belt or timing chain breaks, they occupy the same space at the same time, which means the piston comes up and bends the valves. See Photo 1.

This engine has a timing belt and a timing chain. The belt drives the exhaust cam on the front side of the engine. Then on the back side of the engine, a chain connects the exhaust cam to the intake cam.

The first part of our diagnosis is going to be pretty simple; we’re going to crank the car and listen to what it sounds like. Check out the video at 1:11 to hear what we should hear when a normal engine that’s going to start sounds like. Then listen at 1:22 for what it sounds like when we suspect a broken timing belt or broken timing chain. What you’re hearing is a lack of compression and, odds are, the car’s not going to start. What you’re missing is the squeeze portion of our suck/squeeze/bang/blow engine cycle.

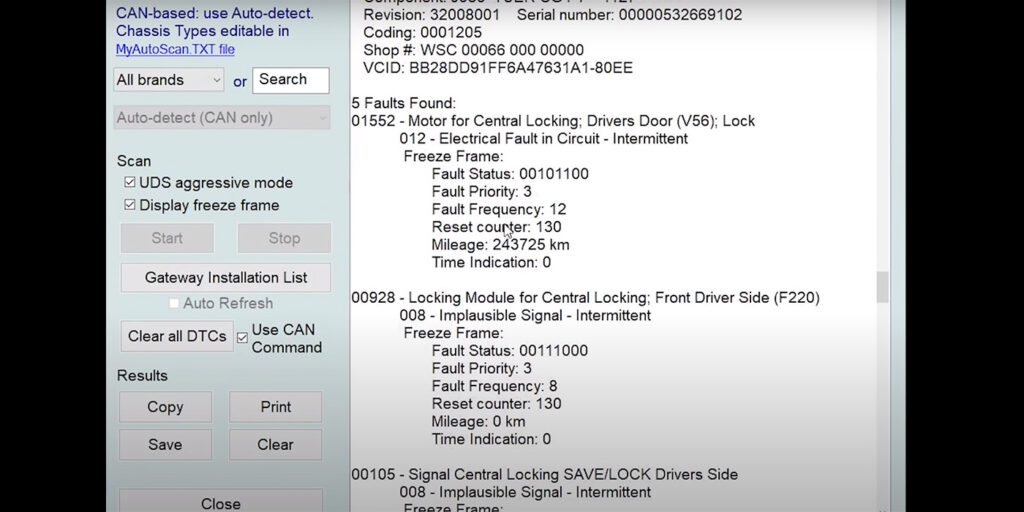

Next up, we’ll do a visual inspection and a full vehicle scan. And you’re probably wondering, “Charles, we have a bad engine, why are we doing a vehicle scan?” Well, it’s part of the diagnostic process for one. Also, I would hate for you to make all these really expensive engine repairs and then come to find out you also have a bad turbocharger that you didn’t know about. So do the full vehicle scan. It gives you a complete picture of what is actually going on with the rest of the car, and we might make different decisions based on what we find.

Luckily for us we have some bad door latches and that’s about it. See Photo 2.

For the visual inspection, we want to look at the overall exterior of the engine. Make sure there are no severe oil or coolant leaks or something really severe like a connecting rod punched through the block. This can be helpful too when we go to order our parts to make sure that we get everything on the first order.

Now, this engine is actually pretty cool because we can look at the camshaft to determine whether we have a belt issue or a chain issue. Whether it’s the belt or the chain, odds are, the damage is going to be the same. However, I want you building good habits and not skipping steps. Think about this from a diagnostic standpoint not just jumping right to the problem.

So we’re going to pull the engine oil cap off and take a look at our cams through there. We could also take out the two T30s from the upper timing cover, pull it back and inspect our belt that way. With the oil cap off you can see the intake cam pretty easily. You have to peek back a little bit in order to see the exhaust cam. You’ll want to have someone crank the engine while you’re looking down the oil fill hole. If you see the exhaust cam turning and the intake cam is not turning, it’s usually the timing chain. If you’re not seeing either one of the cams turning, it’s most likely a timing belt issue.

Typically with this failure it results in bent intake valves, so you could in theory pull the intake and inspect the valves. However, that only gives you part of the story; that doesn’t tell us anything about the exhaust valves or potential damage to the pistons. What I like to do better is pull the ignition coils, pull the spark plugs and run that borescope down the spark plug wells. Now, with the borescope, sometimes it might be challenging to see exactly the damage going on. However, it’s a really good step because you also want to make sure you don’t have something really bad like a hole in the top of the piston, which is super rare but I have actually seen a piston get broken from this exact type of damage.

So clearly we have some internal engine damage that we need to take care of. We do need to get owner authorization before we do a full tear down on this job, but let’s look at what it takes to get this fixed. The cylinder head does need to come off and we need to get valves replaced and maybe more depending on what we find. See Photo 3. On a low-mileage car, you could probably just put new valves in it and send it on its way. On a higher mileage engine like this one, it’s probably worth going to the machine shop for new valves, guides and seals. But either way, you’re going to need to replace the valves that are bent, head gasket, bolts and a bunch of seals. It’s probably also worth pulling the engine oil pan and cleaning and inspecting the oil pickup tube. You also want to make sure on teardown you note any more damage that you find.

Now, if you took this to a shop, you’d probably be looking at a $3,500 to $4,000 repair, depending on where you’re at and how much damage was done. You can also order a whole new cylinder head kit and do the repair yourself. Labor time on this kind of job is generally in the 10 or so hour range.

Continuing with our inspection, we find that it was in fact the timing chain that broke. It feels like this car probably didn’t have the best oil change history throughout its life — the tensioner was all in pieces. Luckily though, two things: one, our high pressure fuel pump and the follower for it are not worn through, so we don’t need a camshaft, which is awesome. And two, the cover isn’t busted up. This cover costs around $900 new, so I’m thankful that this isn’t damaged, which saved a bunch of money. But, we’ve still got to pull the head and get valves and do a timing belt and a timing chain and hopefully don’t find anything else more wrong with it.

Be sure to check out the video and let me know if you have any comments or questions.