The latest SAE J2810 standards for refrigerant recovery machines, which replace the previous SAE J1732 standards, now require these machines to recover 95% of the refrigerant from an A/C system within 30 minutes. Older recovery machines could take much longer, and sometimes left as much as 30% of the refrigerant charge in the system. Consequently, if the old refrigerant was dirty or contaminated, it would contaminate the new refrigerant when the A/C system was recharged.

The new J2810 standard does not require shops to replace existing refrigerant recovery machines. But if you are having refrigerant cross-contamination issues or comebacks because of refrigerant-related problems, the underlying cause might be your equipment. Replacing your old inefficient refrigerant recovery machine with a new one that meets the latest J2810 standards could be the answer to your dilemma.

A couple of years ago, SAE also released a new standard for recovery/recycling machines and recharging stations. The J2788 standard also requires 95% refrigerant recovery within 30 minutes, more accurate weighing of the refrigerant when recharging (plus or minus 0.5 oz.), an automatic purge cycle to vent air from refrigerant storage tanks, and a higher level of purity for recycled refrigerant.

Of course, meeting these specifications is not enough if you want the best equipment available. Many recovery/recycling/recharging machines now incorporate fully automatic controls that allow a technician to do something else once the unit has been connected to a vehicle and started. Automation combined with smart diagnostics that can detect faults (such as a leaky A/C system that won’t hold a vacuum) can boost shop productivity and eliminate mistakes that can cause comebacks.

Refrigerant Identifiers

Though R-12 is mostly history, cross-contamination issues persist in the field. People are recharging R-134a A/C systems with all kinds of concoctions. Consequently, if you don’t have a refrigerant identifier, you have no way of knowing what’s inside a vehicle’s A/C system. It could be good refrigerant or it could be junk.

Many recovery/recycling machines are now available with a built-in refrigerant identifier. Or, you can by a stand-alone identifier to use with existing equipment. Either way, it’s a must-have piece of equipment for anybody who services A/C systems today. Some identifiers give a “good” or “bad” indication based on the relative purity of the refrigerant (98% or higher is usually considered good). The more sophisticated identifiers display the percentages of various gases in the refrigerant, including air and hydrocarbons (flammable refrigerants). You can also use an identifier to check the quality and purity of refrigerant in a vehicle that is having cooling problems, to check your recovery and storage tanks, and to check the quality of the refrigerant you buy.

Something else you don’t want in your A/C service equipment is A/C sealer. Some of these products can gum up your equipment and cause all kinds of havoc. Using an identifier that can detect the bad chemicals and/or an in-line filter that stops the gunk before it can be pulled into your equipment is a wise investment that will reduce down time and maintenance costs.

Leak Detection

Some type of leak detection capability is also essential for finding refrigerant leaks. Fluorescent dye that glows yellow or green when illuminated with ultraviolet (UV) light is certainly useful for finding small leaks. But it takes time to find really small leaks using UV light, and may be no help whatsoever when searching for evaporator leaks. So you also need a good electronic leak detector that can sniff out leaks in places where dye can’t be seen or takes too long to find the leak.

If you are buying an electronic leak detector, make sure it meets the latest SAE J2791 standards, which require much greater sensitivity and accuracy than the former SAE J1627 standard. The latest detectors can find leaks as small as 4 grams per year, which is more than three times better than the previous generation of leak detectors. Additional settings allow the sensitivity to be adjusted to detect leaks of 7 or 14 grams per year. The new standard also requires the detectors to not trigger false alarms for extremely small leaks (2 grams a year or less) that are insignificant.

Diagnosis

Nothing beats a good high and low pressure gauge set for diagnosing A/C problems — if a technician knows how to use them. Like any skill, it takes training and experience to learn how to use a gauge set. An easier alternative for many is to buy equipment that takes much of the guess-work out of diagnosing common problems in the refrigeration circuit. These diagnostic units are not cheap, but they essentially do the job of an experienced A/C technician with the press of a button. These units typically look at the high and low side pressure readings to detect problems that affect cooling performance. The units are not fool-proof, but they do provide a relatively quick and easy way to verify A/C system performance — and they don’t require the skills of a master technician to operate.

Another tool that has become a necessity for troubleshooting late-model automatic climate control systems is a scan tool. A scan tool can access fault codes, check sensor inputs and run various self-diagnostic tests to test the operation of the A/C system. On many vehicles, a scan tool is also required for various A/C system reset and relearn procedures. So if you don’t have a scan tool that can access the body computer or climate control module, you’ll be sending a lot of your work back to the new car dealer for diagnosis and repairs.

A good digital volt ohm meter (DVOM) is also essential for troubleshooting electrical circuits, relays and other electronic components in the A/C system.

Flushing Equipment

Moisture contamination causes acids and sludge to form inside A/C systems. If not removed, the sludge may gum up the orifice valve or expansion valve, and/or cause the compressor to fail. Condensers can also be contaminated with metallic debris if a compressor fails.

Though many condensers cannot be flushed to remove sludge or contaminants, some can. The same goes for hoses and lines. A good flushing machine and the right kind of solvent can give you the flexibility to do this kind of work if the situation warrants it.

Line Repair Tools

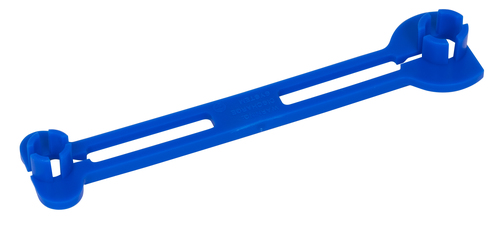

Having the ability to fabricate and repair damaged or leaking A/C lines and hoses is certainly a plus for any shop. To do this kind of work, you need a kit for forming end fittings on lines to accept compression fittings and crimping tools for installing various types of hose fittings.

New Equipment Requirements Down the Road?

The debate over the future of R-134a still remains uncertain. In Europe, the automakers are moving toward R-744 (carbon dioxide) as the next generation refrigerant. But R-744 requires extremely high operating pressures and is totally incompatible with today’s A/C systems and service equipment.

HFO-1234yf, which is DuPont’s latest refrigerant, is being touted as the best alternative to R-134a. It has very similar operating characteristics (same temperature and pressure curves as R-134a), pressures and cooling performance; there are no materials compatibility issues; and it appears to have lower flammability than R-152a (another potential successor to R-134a). The main attraction with HFO-1234yf is its low Global Warming Potential rating — only 4 versus 1,200 for R-134a. Politics and economics will ultimately decide whether automakers replace R-134a with something else or continue using the same refrigerant they have used since 1995. Any such change is still years away, so don’t let that influence your A/C service equipment buying decisions today.